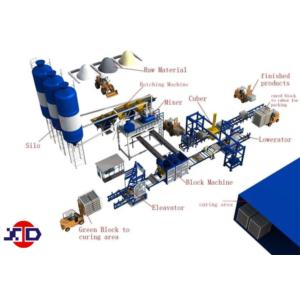

OEM ODM Automatic RGV curing stacking production line

#### **Description**

The Automatic RGV Curing Stacking Production Line is a cutting-edge system designed to enhance efficiency in the handling and curing of products. This innovative line integrates various components, including a self-retaining hole high-level palletizing system, elevators, pushing devices, and more, to streamline the production process. Each unit is engineered for precision and reliability, ensuring that your operations run smoothly and effectively. The system is equipped with advanced features such as wireless communication for real-time monitoring and control, making it a valuable addition to any production facility.

#### **Specifications**

| Number | Classification | Name | Specification | Unit | QTY. | Power (KW) | Remark |

|---|---|---|---|---|---|---|---|

| 1 | Self-retaining hole high-level palletizing system | Products Feeder | XD-1200-B | Set | 1 | Chuck specifications are made according to the customer’s pallet size. Standard brick conveyor length is 8m. | |

| 1 | Elevator | XD-1200-B | Set | 1 | 5.5 | ||

| 1 | Pushing pallet device | XD-1200-B | Set | 1 | |||

| 1 | Pushing Block device | XD-1200-B | Set | 1 | 6.2 | ||

| 1 | Divide brick device | XD-1200-B | Set | 1 | |||

| 1 | Retain Hole platform | XD-1200-B | Set | 1 | |||

| 1 | High-level stacker | XD-1200-B | Set | 1 | 1.5 | ||

| 1 | Lowerator | XD-1200-B | Set | 1 | 1.5 | ||

| 1 | Pallet Turning Device | XD-1200-B | Set | 1 | 2.2 | ||

| 1 | Pallet Conveyor | XD-1200-B | Set | 1 | |||

| 1 | Brick conveyor | XD-1200-B | Set | 1 | 5.5 | ||

| 1 | Control system | Components from Schneider and ABB | Set | 1 | |||

| 2 | Hydraulic system | Low-voltage DC motor | Set | 2 | 4/15 |

#### **Additional Information**

The system is designed with user-friendly features, including a wireless WIFI system for remote monitoring and control. Each component is carefully selected for durability and efficiency, ensuring a long-lasting and reliable production line. The automatic features and high-level stackers not only increase productivity but also minimize labor costs.