Description

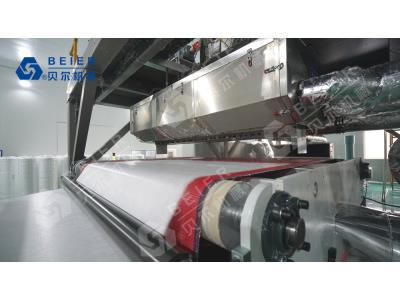

The PVC Profile Extrusion Line is a cutting-edge production system designed for the efficient manufacturing of PVC profiles. This advanced line ensures high extrusion efficiency and reliable performance, making it an essential addition to any production facility. With a user-friendly interface and both digital PLC and manual temperature control options, operators can easily manage the extrusion process. The production flow includes a series of key stages: material heating, cooling mixing, feeding, extrusion molding, cooling, printing, haul-off, cutting, and stacking.

Specifications

| Component | Details |

|---|---|

| Feeder | Designed to feed material into the extruder. |

| Extruder | Features world-renowned electrical components (Siemens, Schneider, ABB), high torque gearbox with NSK/SKF bearings, and a user-friendly intelligent PLC control system. |

| Die Head | Made from 3Cr13/3Cr17 material, includes extrusion die head, calibrator, and cooling tank, suitable for single and co-extrusion. |

| Calibration Table | Includes full set of vacuum and water pump; dimensions: Width 240mm, Length 6000mm; features independent operation panel. |

| Haul Off | Upper/lower caterpillar driven separately with speed control by inverter; features fast change type pads for easy operation. |

| Cutter | Lifting saw cutter with double station dust collection system; synchronous driving by air cylinder or servo motor control. |

| Stacker | Constructed from stainless steel 304; discharge driven by air cylinder. |

| Hot Stamping Machine | Provides decorative pattern and film protection for product surfaces. |

Additional Information

This PVC Profile Extrusion Line is designed for ease of maintenance and operation, ensuring minimal downtime and maximum productivity in manufacturing processes.