Description

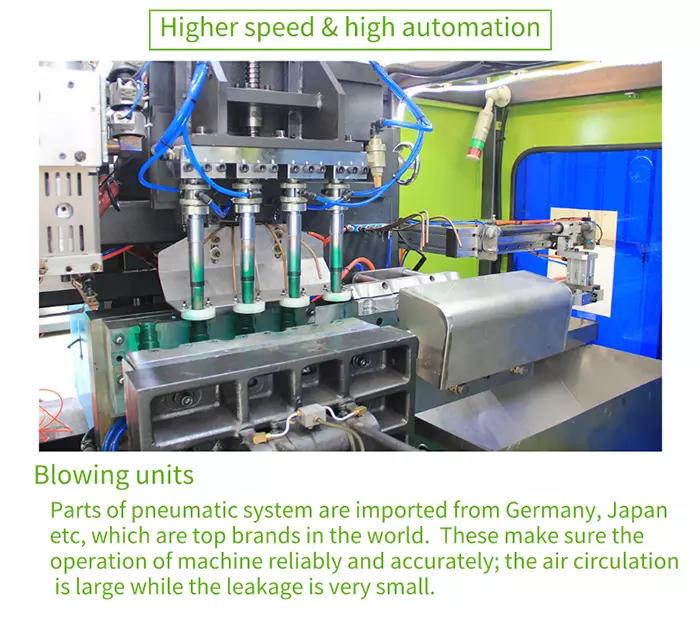

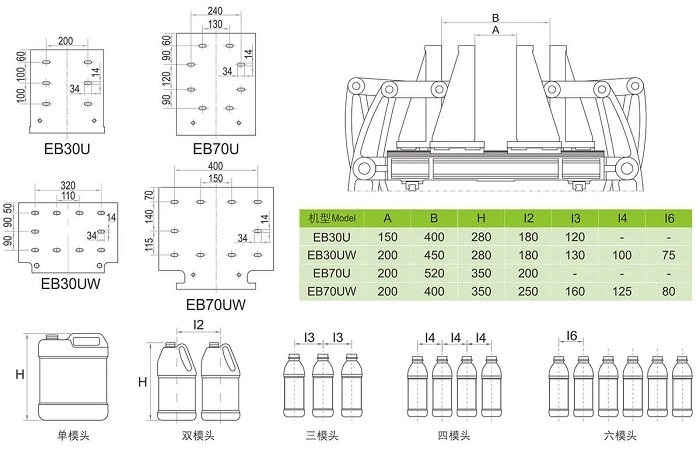

The High Speed Double Station Blow Molding Machine EB30U/EB70U is a cutting-edge solution designed for the efficient manufacturing of bottles and containers, with a maximum capacity of up to 10 liters. Crafted for versatility, this machine is ideal for producing a wide array of products including daily necessities, toiletries, and beverages. Its robust construction and advanced features ensure low friction, high speed operation, and top-quality output.

Key to its performance is the toggle balance clamping structure, which enhances the speed and efficiency of mold operations. The machine leverages finite element analysis for its design, utilizing high-intensity nodular cast iron for the platen and frame, ensuring durability and strength. With high-speed mold clamping and advanced heating controls, the EB30U/EB70U stands out as a leader in blow molding technology.

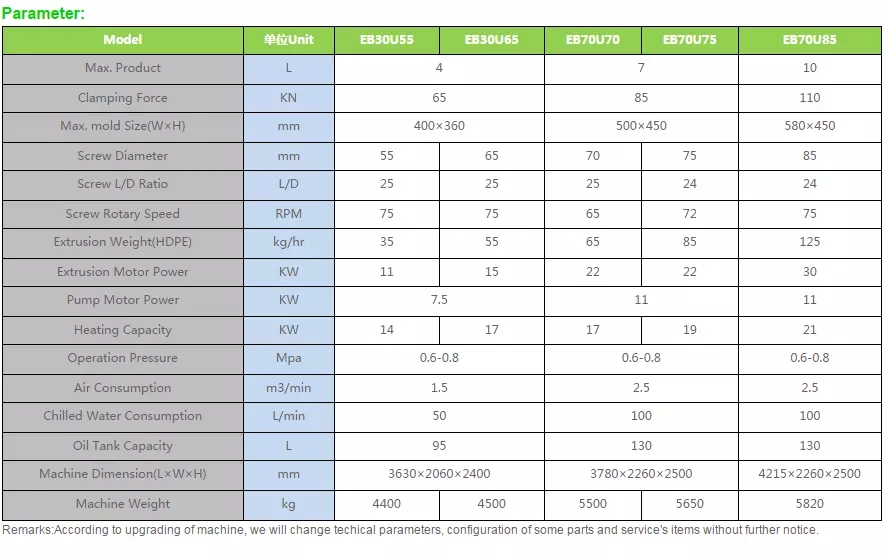

Specifications

| Attribute | Details |

|---|---|

| Max Bottle Capacity | 10 L |

| Clamping Force | 65~110 KN |

| Extrusion Weight (HDPE) | 35~125 kg/hr |

| Applications | Daily necessities, toiletries, beverages, etc. |

| Heating Control | Multiple-way PID controlled temperature |

Additional Information

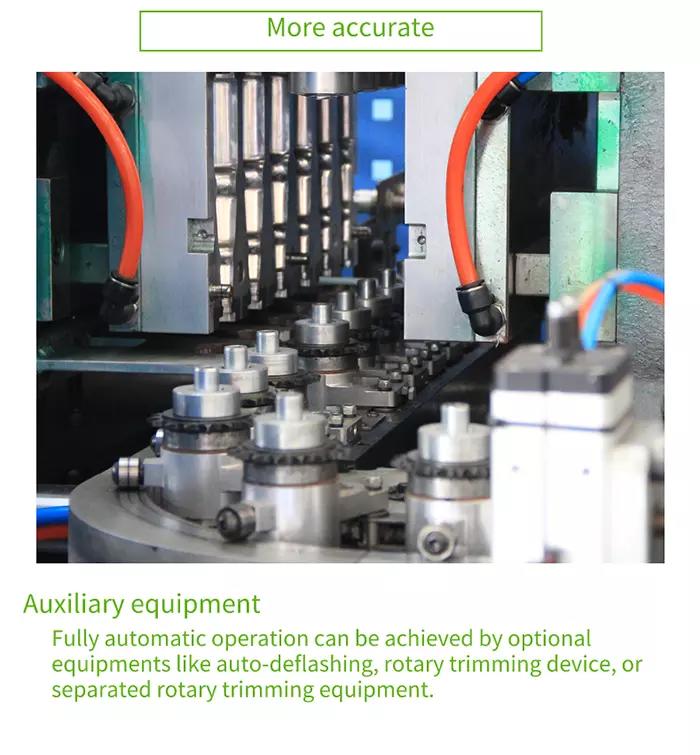

- Toggle balance clamping structure for low friction and high speed.

- Platen, toggle, and frame made from high-intensity nodular cast iron.

- High-speed mold clamping oil cylinder with differential speed function.

- Specially designed screw for optimal plasticizing and stable extrusion.

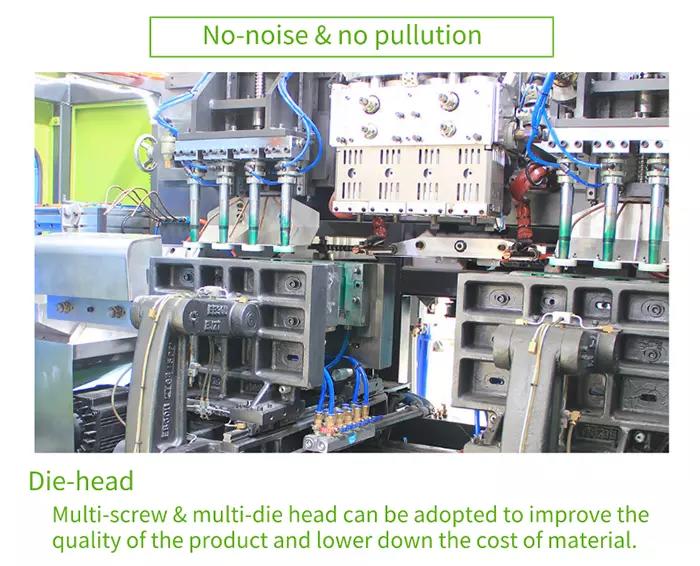

- Multi-screw and multi-die head options available to improve product quality and reduce material costs.