OEM ODM V-series Energy-Saving Injection Molding Machine

Description

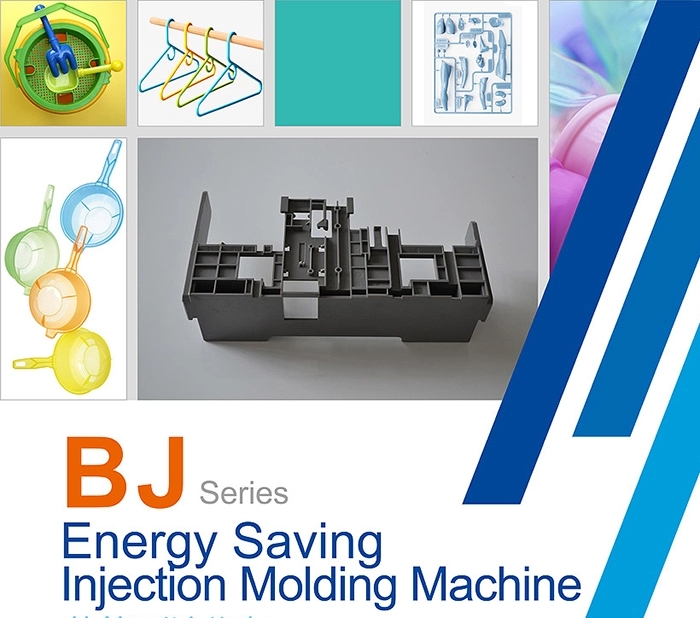

The V-series Energy-Saving Injection Molding Machine is a state-of-the-art equipment designed to enhance efficiency and sustainability in the manufacturing process. This standard injection molding machine features a new driving system that significantly reduces energy consumption, achieving up to 50% energy savings compared to traditional hydraulic machines. The servo motor system ensures precise injection accuracy and speed, especially during the pressure hold and cooling stages.

With a clamping force ranging from 50 to 1380 tons, it is suitable for a variety of applications including:

- Food and beverage packaging

- Home appliances

- Electrical components

- Automotive parts

The user-friendly control system enables operators to effortlessly manage various process needs, while the advanced lubrication system automatically supplies grease to key friction points, ensuring optimal performance and longevity.

Specifications

| Attribute | Description | Unit | Value |

|---|---|---|---|

| Clamping Force | Maximum clamping force for mold | KN | 6800 |

| Opening Stroke | Distance the mold opens | mm | 930 |

| Max. Daylight | Maximum daylight between platens | mm | 1870 |

| Platen Size | Dimensions of clamping platens | mm | 1340 x 1340 |

| Space Between Bars | Distance between fixed and moving platens | mm | 940 x 940 |

| Max. Mold Height | Maximum height of molds | mm | 940 |

| Min. Mold Height | Minimum height of molds | mm | 350 |

| Ejector Stroke | Distance the ejector moves | mm | 265 |

| Ejector Force | Force applied by the ejector | KN | 184 |

| Screw Diameter | Diameter of the injection screw | mm | 90 |

| Screw L/D Ratio | Length to diameter ratio of the screw | L/D | 22.4 |

| Injection Pressure | Pressure for injection of materials | MPa | 190 |

| Shot Volume | Volume of material shot per cycle | cm3 | 2863 |

| Screw Stroke | Distance the screw moves during injection | mm | 450 |

| Hydraulic System Pressure | Operating pressure of the hydraulic system | MPa | 17.5 |

| Pump Motor Power | Power rating of the pump motor | KW | 55/25.1+30.8 |

| Heater Power | Heater power for melting materials | KW | 38 |

Additional Information

For optimal operation, regular maintenance of the lubrication system is recommended to ensure longevity and performance. The machine comes with a comprehensive user manual, detailing setup, operation, and maintenance procedures.