Description

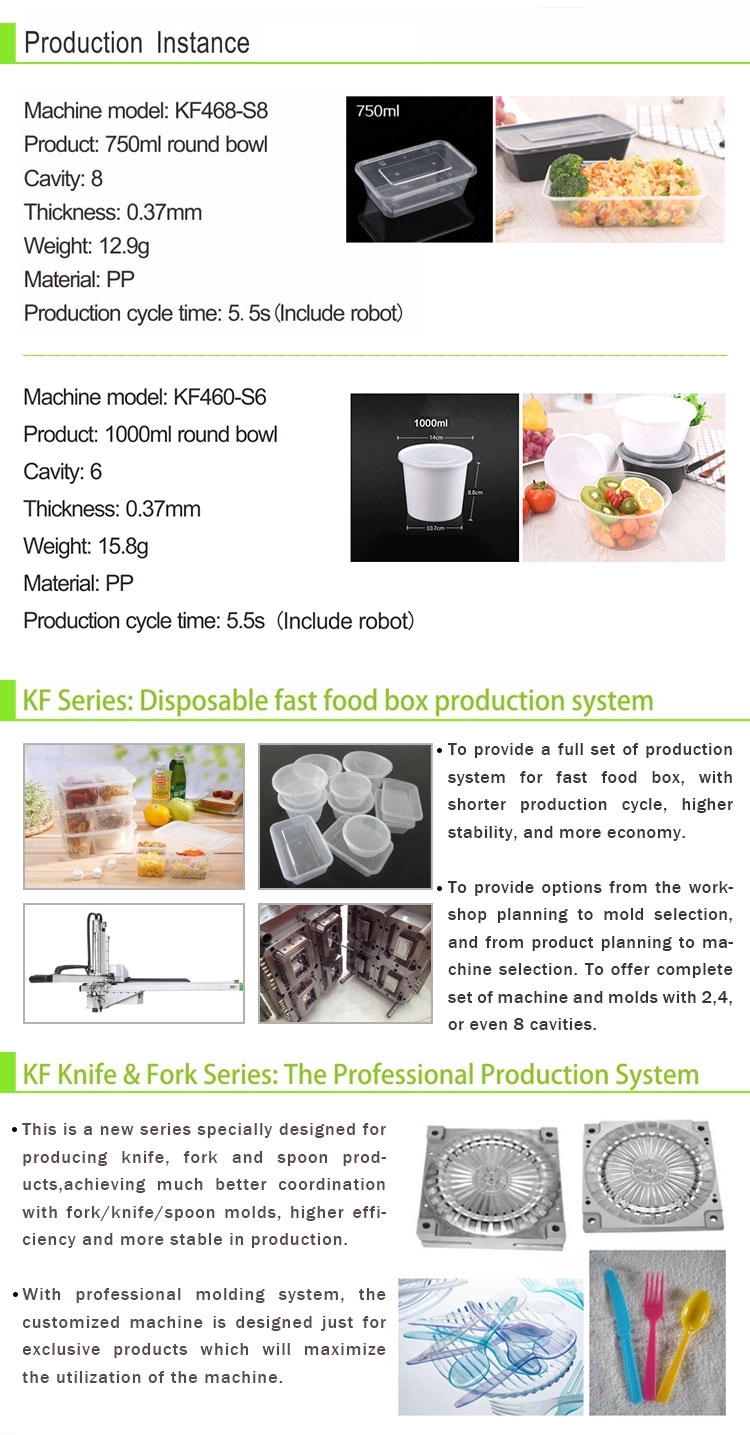

The KF Series High-Speed Injection Molding Machine is specially designed for producing thin-wall plastic products such as cutlery (containers, spoons, forks, and knives). This innovative machine incorporates an advanced injection system that allows for quicker solidification of thin-wall products, achieving energy savings between 30% and 50% compared to standard models. The KF series stands out with its exceptional features:

- Energy-Saving: Utilizing a servo motor with energy-saving controlled hydraulic systems, this machine significantly reduces electricity consumption.

- Low Temperature Injection: Maintains high tenacity and toughness of products while enhancing energy efficiency.

- Low Pressure Injection: Ensures better mechanical protection and longevity of molds, minimizing stress and deformation in molded products.

- Fast Response Speed: The optimized control system achieves a shooting rate of just 0.3 seconds.

Specifications

| Description | Unit | KF460-S6 |

|---|---|---|

| Clamping Force | KN | 4600 |

| Opening Stroke | mm | 600 |

| Max. Daylight | mm | 1270 |

| Platen Size | mm | 1070 x 1050 |

| Space Between Bars | mm | 690 x 670 |

| Max. Mold Height | mm | 670 |

| Min. Mold Height | mm | 250 |

| Ejector Stroke | mm | 150 |

| Ejector Force | KN | 77 |

| Screw Diameter | mm | 55 |

| Screw L/D Ratio | L/D | 24 |

| Injection Pressure | MPa | 180 |

| Shot Volume | cm3 | 594 |

| Screw Stroke | mm | 250 |

| Screw Speed | rpm | 300 |

| Hydraulic System Pressure | MPa | 17.5 |

| Pump Motor Power | KW | 40 + 40 + 16 |

| Heater Power | KW | 30.4 |

Additional Information

For effective packaging and shipping, it is recommended to follow standard practices tailored to the specifications of this machine, ensuring proper handling to maintain its performance standards.