OEM ODM TAPM1010 HIGH SPEED CNC ANGLE PUNCHING MARKING & SHEARING MACHINE

Description

The TAPM1010 High Speed CNC Angle Punching, Marking & Shearing Machine is a specialized piece of equipment designed for the angle steel tower industry, electric power fittings, structural storage facilities, and construction industries. This advanced machine efficiently performs punching, marking, and shearing processes on angle steel, enhancing productivity and precision in manufacturing.

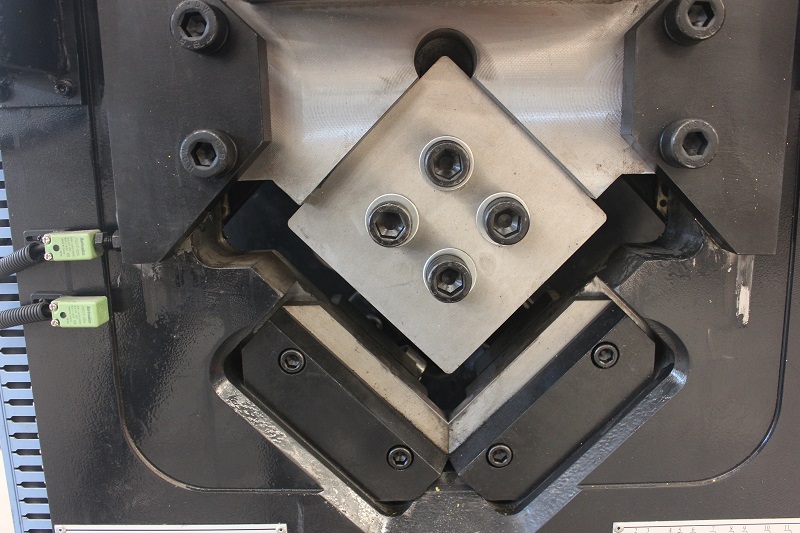

Equipped with a cutting-edge transverse conveyor, rotating loading system, and CNC infeed carriage, the TAPM1010 ensures seamless operation. Its robust construction includes a punching unit, marking unit, and cutting unit, along with hydraulic, electrical, and pneumatic systems, contributing to its exceptional performance and reliability.

Key Features:

- High feeding and punching speeds significantly boost production efficiency, capable of processing 9 to 10 tons of 50×50×4mm angles in just 8 hours.

- Innovative design with patented pressing angle device, NC infeeding carriage, material supporting device, and clamping claws.

- PLC module control with servo motor in feeding for high efficiency and precise workpiece handling.

- User-friendly programming options, supporting manual input or NC.1 file reading generated by TEKLA software.

- Complete automation for marking, punching, and shearing, with a pneumatic turnover device for easy unloading.

- Durable and stable marking unit design, featuring an enclosed frame.

- Single blade shearing system that conserves raw materials.

- Advanced feeding conveyors equipped with double linear guides for improved speed and accuracy.

Specifications

| Model | TAPM1010 |

|---|---|

| Functions | Punching, marking, shearing |

| Angle size (mm) | 40x40x3 – 100x100x10 |

| Max. Punching (dia. х thi.) (mm) | Φ26×10 (Q345) |

| Punching force (kN) | 600 |

| Marking force (kN) | 630 |

| Cutting force (kN) | 1200 |

| Max. length of blank (m) | 10 or 12 |

| Max. length of finished (m) | 8 |

| Punches per side | 2 |

| Group of Marking letters | 4 |

| Dimension of letter (mm) | 14x10x19 |

| CNC axes | 3 |

| Cutting mode | Single blade cutting |

| Feeding speed of angle (m/min) | 80 |

| Programming mode | Lofting software or manual program |

| Overall size(mm) | 25000x6500x2500 |

| Net weight(kg) | About 13000 |

| Total power(KW) | About 38 |

Additional Information

This machine is designed for optimal safety and longevity. The enclosed marking unit enhances stability and extends the lifespan of the marking apparatus. All main cables, including rotary encoder and PLC communication cables, utilize shielding twisted-pair technology to prevent signal interference, maintaining accuracy during operation. The machine also features double accumulators to improve punching speed and a high-quality DENISION pump for the hydraulic motor, ensuring lower noise levels.