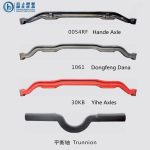

Description

The front axle is a critical component designed for durability and performance in various vehicle applications. Engineered using cutting-edge technology, it is manufactured on advanced production lines featuring two sets of 8000-ton double disk friction presses, four sets of 1600-ton high power screw presses, and six KUKA robots. This ensures precision and reliability in every unit produced.

Our manufacturing process includes state-of-the-art forging equipment, heat treatment lines for quenching and tempering, and meticulous inspection protocols such as fluorescent magnetic particle flaw detection. This guarantees that each front axle meets the highest industry standards for quality and safety.

Specifications

| Feature | Details |

|---|---|

| Press Types | 8000 ton double disk friction presses, 1600 ton high power screw presses |

| Robots | KUKA robots |

| Heat Treatment | Quenching and tempering |

| Inspection | Fluorescent magnetic particle flaw detection |

| Production Lines | Machining lines, paint line |

Additional Information

To ensure optimal performance and longevity, regular maintenance and inspections are recommended. Always adhere to the manufacturer’s guidelines for installation and usage.