Description

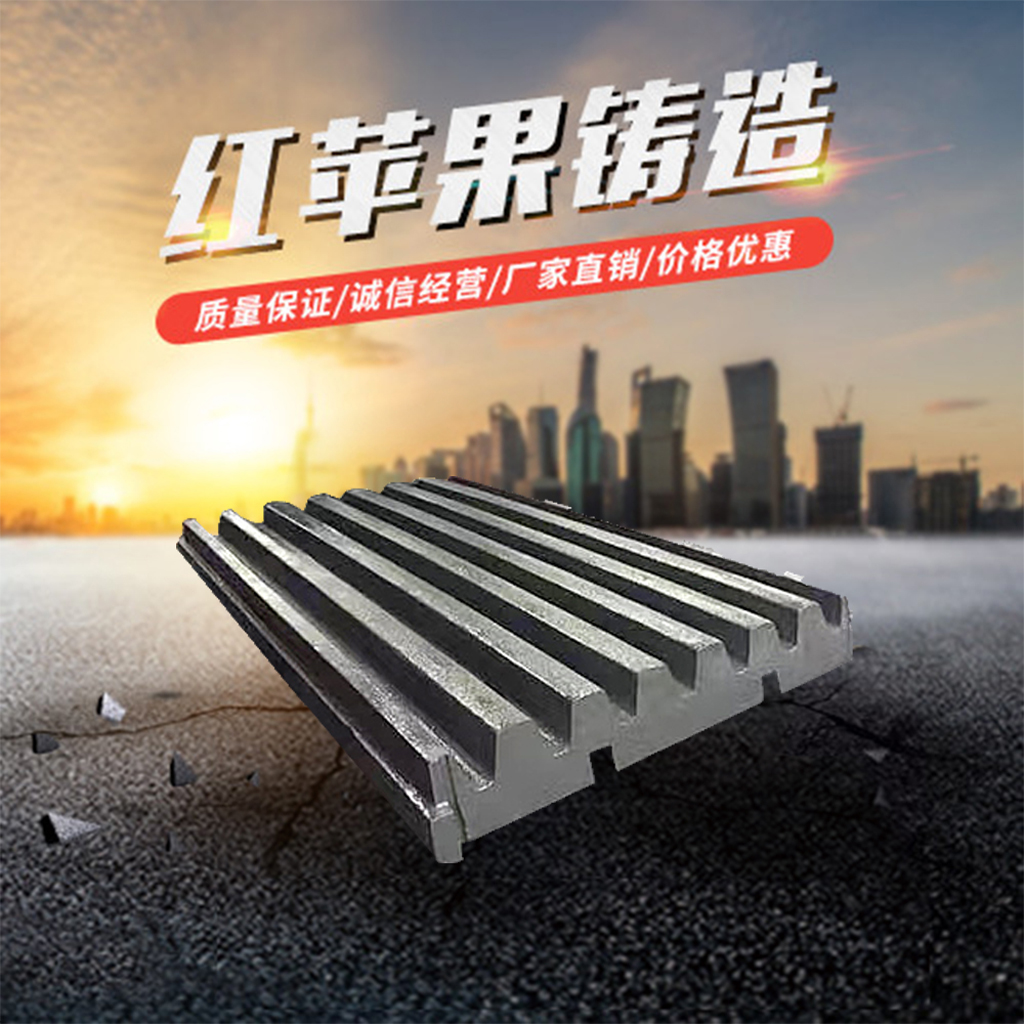

The Crusher Jaw Plate is a vital component for jaw crushers, designed to withstand the rigors of crushing various materials. Known by many names including moving jaw plate, static jaw plate, and tooth plate, this product is essential for achieving optimal crushing efficiency. Made primarily from high manganese steel and manganese chromium alloy, the jaw plate demonstrates exceptional durability and wear resistance. Its innovative casting process utilizes V method, lost foam, and sodium silicate sand casting techniques to enhance performance and longevity.

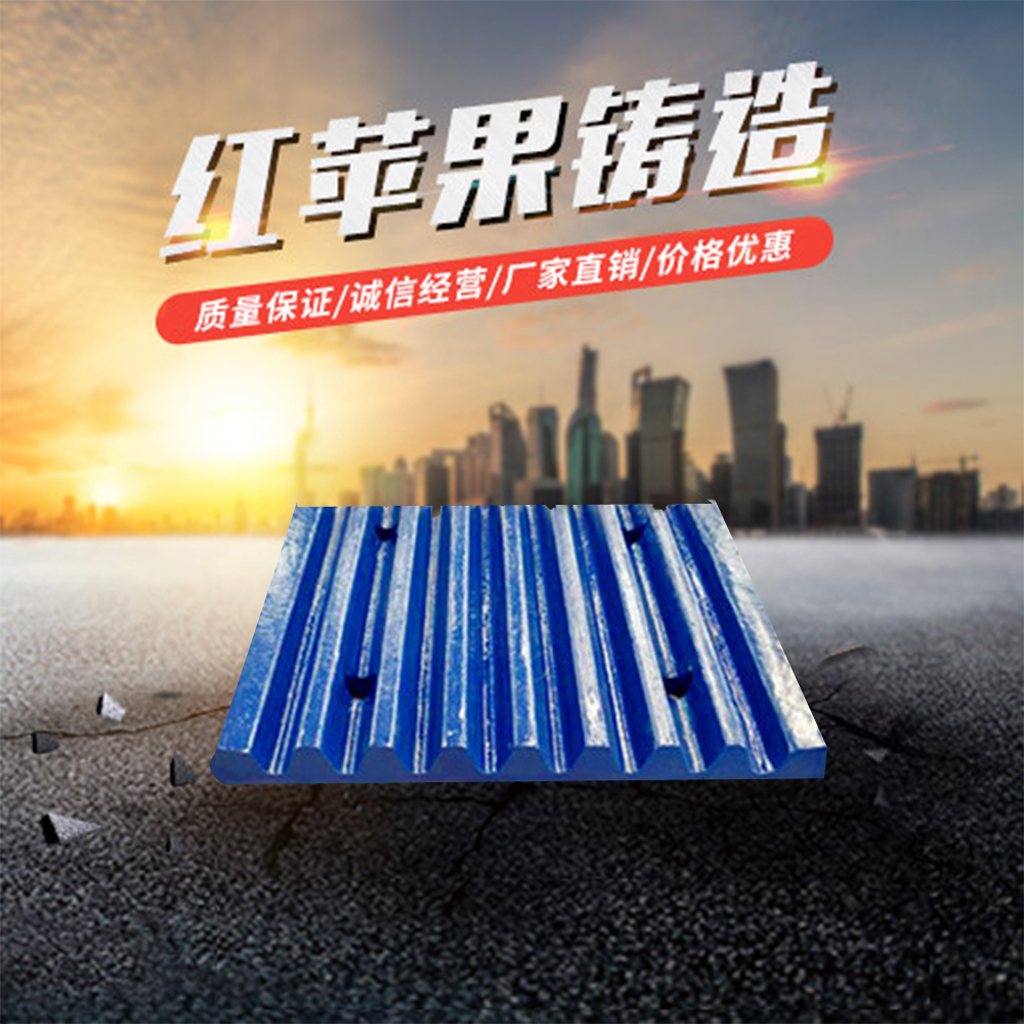

This jaw plate is suitable for processing a wide range of materials such as river pebbles, granite, basalt, iron ore, limestone, quartz, and even precious metals like gold and copper. Its versatility makes it ideal for applications in sand and gravel yards, mining operations, coal mining, concrete mixing stations, and power plant desulphurization.

The high manganese steel jaw plate has revolutionized the industry by providing improved toughness and extended service life compared to traditional cast iron and hardened steel options. As jaw crushers exert immense pressure during operation, the jaw plate’s role is crucial, being the part that directly interacts with the material being crushed.

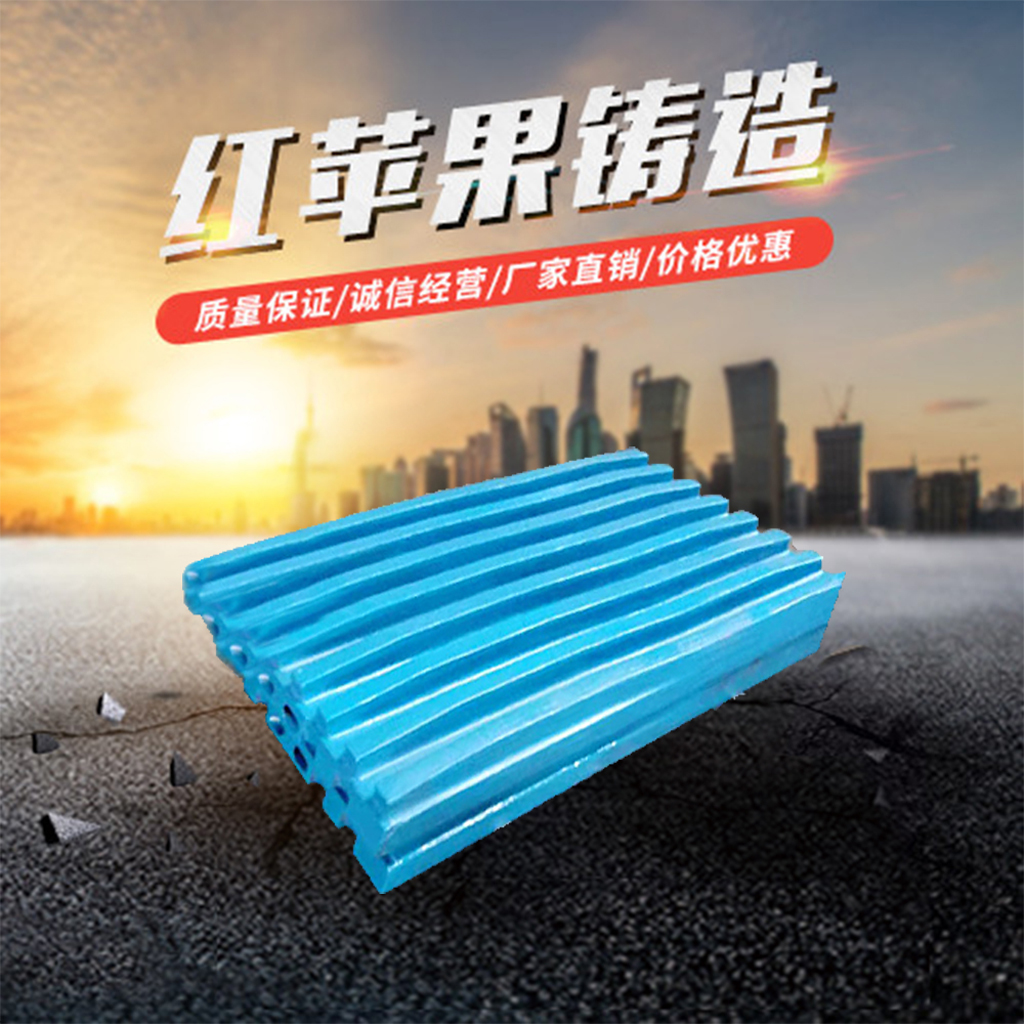

With advancements in technology, various types of jaw plates are available, including medium manganese steel and bimetal composite options, each tailored to enhance performance based on specific operational conditions. This ensures that the Crusher Jaw Plate remains a top choice for heavy-duty grinding and crushing needs.

Specifications

| Material | Type | Applications | Process |

|---|---|---|---|

| High Manganese Steel (Mn13, Mn18) | Fixed and Movable Jaw Plates | River Pebbles, Granite, Basalt, Iron Ore, Limestone, Quartz, Gold, Copper | V Method, Lost Foam, Sodium Silicate Sand Casting |

| Manganese Chromium Alloy (Mn13Cr2, Mn18Cr2) | Wear-Resistant Jaw Plates | Mining, Coal Mining, Concrete Mixing Station | Composite Alloy Casting |

| Medium Carbon Low Alloy Cast Steel | Durable Jaw Plates | Sand and Gravel Yards, Power Plant Desulphurization | Heat Treatment Process |

Additional Information

- Service life of high manganese steel jaw plates exceeds 50% compared to similar products.

- Medium manganese steel offers improved performance when dealing with softer materials.

- Bimetal composite plates combine high wear resistance with good impact toughness.