OEM ODM floor tiles making machines

Description

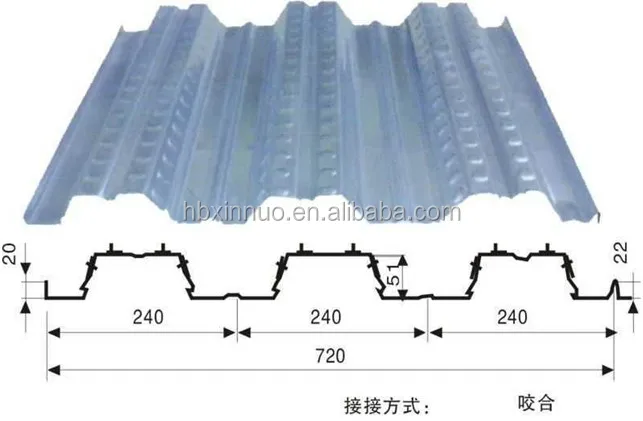

Introducing our innovative floor tiles making machines, designed to revolutionize the production of roofing sheets and tiles. These advanced machines utilize cutting-edge technology to create high-quality floor tiles with enhanced durability and aesthetics. The gutter cold roll forming machine is equipped with a robust structure, including an uncoiler, feed leading table, main machine, formation cutting device, hydraulic system, and control system, ensuring seamless operation and superior results.

The large size car panel metal forming equipment features a cold roll forming machine that bends pipes to create a unified drainpipe, significantly improving project integration and longevity compared to traditional materials. With a design aimed at enhancing project visuals, this machinery is essential for any production line focused on quality and efficiency.

Specifications

| No. | Main Parameter | Details |

|---|---|---|

| 1 | Suitable to process | Color steel plate |

| 2 | Width of the plate | 1220 mm |

| 3 | Rollers | 14-18 rows |

| 4 | Dimensions | 11.6 * 1.6 * 1.5 m |

| 5 | Power | 7.5 + 4 kW |

| 6 | Thickness of the plate | 0.3 – 0.8 mm |

| 7 | Productivity | 8-12 m/min |

| 8 | Diameter of the roller | Φ70 mm |

| 9 | Weight | About 6.8 T |

| 10 | Voltage | 380V 50Hz 3 phases |

| 11 | Rolling material | Carbon Steel 45# |

| 12 | Material of the cutting plate | Cr12 |

| 13 | Processing precision | Within 1.00 mm |

| 14 | Control system | PLC control |

| 15 | Side panel of machine | 14 mm |

| 16 | Main structure of the machine | 300 H steel |

Additional Information

Equipment components include a manual uncoiler, roll forming machine, computer control system, hydraulic control system, cutting mechanism, and run-out table, providing a comprehensive solution for efficient tile production.

Product Pictures