OEM ODM 600-305 Complete Hydraulic Arch Metal Sheet Roofing Roll Forming Machine

Description

The 600-305 Complete Hydraulic Arch Metal Sheet Roofing Roll Forming Machine is designed for efficiency and precision in creating high-quality arch roofing sheets. This robust machine caters to a variety of customer needs with its advanced features and reliable performance. Engineered by a professional team, it ensures long-lasting utility and operates under strict quality control standards. The machine is equipped with a comprehensive technical guidance system, making it suitable for both new and experienced users. Its manufacturing process meets international safety export standards, promising durability and operational longevity.

Notably, this machine offers a cost-effective solution by producing its own accessories, which significantly reduces external procurement costs. The 600-305 model has garnered a strong reputation globally, being favored by major companies for repeat orders due to its exceptional quality and reasonable pricing.

Specifications

| Feature | Details |

|---|---|

| Production Name | Bohai Arch Roof Roll Forming Machine |

| Size | 8900 mm × 2100 mm × 2300 mm (With Single Axle 4 Tires) |

| Total Weight | About 10 Ton |

| Thickness of Bending Leaf | 10mm Thickness, Processed by CNC |

| Cutting Blade | 12CrMov Material, Heat Treatment |

| Cutting Type | Mechanical Cutting |

| Forming Type | Roll-Formed and Length-Set Cutting |

| Power | Total Motor Power: 15.2 KW Roll Forming Motor Power: 5.5 KW Cutting Power: 3.0 KW Bending Power: 3.0 KW + 1.5 KW |

| Seaming Power | 1.1 KW + 1.1 KW |

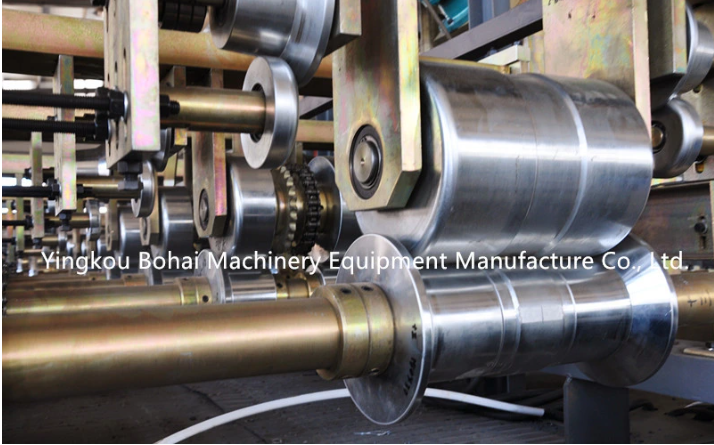

| Roller Material | 45# High-Quality Steel, Quenched HRC 55~65, Hard Chrome Plating |

| Shaft Material | 45# High-Quality Steel, Galvanized |

| Stand of Molding | 13+1 Steps |

| Feeding Width | 600 mm |

| Effective Width | 305 mm |

| Using Rate | 50.8% |

| Thickness Coil | 0.5-1.6 mm |

| Speed | Forming Part: 15 m/min Bending Part: 13 m/min Seaming Part: 16 m/min |

| Suitable Span | 4~24 m |

| De-Coiler | Inner-Diameter of Coil: 450 mm ~ 650 mm Max Width of Coil: 600 mm ~ 620 mm Load: 10 Ton |

Additional Information

- The machine offers overseas technical guidance services.

- After-sales service includes timely follow-up and engineering advice.

- The machine is designed to meet safety export standards.