Description

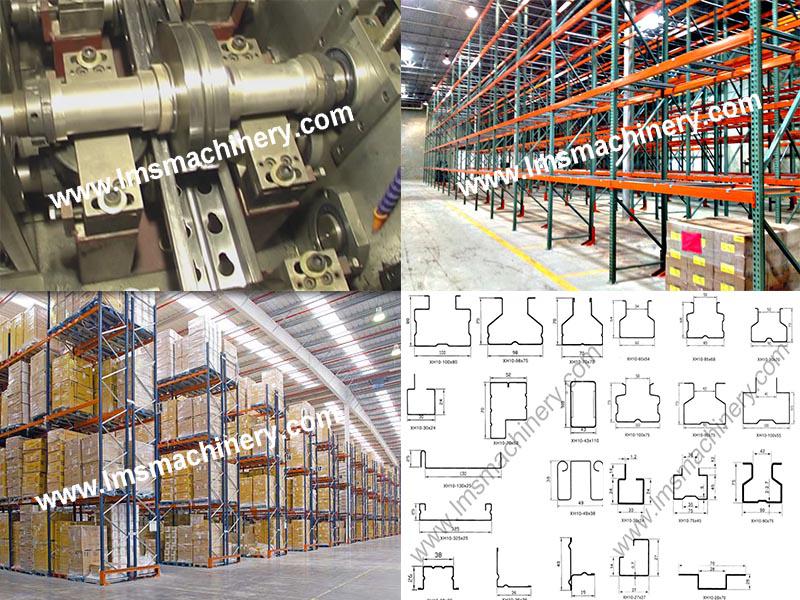

The Omega Rack Upright Roll Forming Machine is engineered for precision and efficiency in producing high-quality rack profiles. This advanced machine features on-line hole punching, making it an ideal solution for manufacturers looking to streamline their production process. Designed to work with carbon steel and CR steel coils, it accommodates a variety of material specifications, ensuring versatility in production.

With a robust structure and user-friendly interface, the machine integrates multiple processes including decoiling, feeding, flying hole-punching, roll forming, and hydraulic cutting-off, resulting in a seamless production line. The machine’s capability to handle material thicknesses between 1.5 mm and 2.0 mm and produce profiles with precise dimensions makes it a valuable asset for any manufacturing facility.

Specifications

| Attribute | Details |

|---|---|

| Materials | Carbon Steel Coil, CR Steel Coil |

| Material Thickness | 1.5 – 2.0 mm |

| Profile Width | 76.2 mm |

| Profile Height | 41.3 mm |

| Profile Specification | C76.2X41.3X1.5-2.0, with Rib |

| Machine Components |

|

Additional Information

The production process of the Omega Rack Upright Roll Forming Machine is highly efficient, encompassing material coil decoiling, feeding, flying hole-punching, roll forming, and hydraulic cutting-off, culminating in the creation of precise rack profiles controlled by a PLC system.