Description

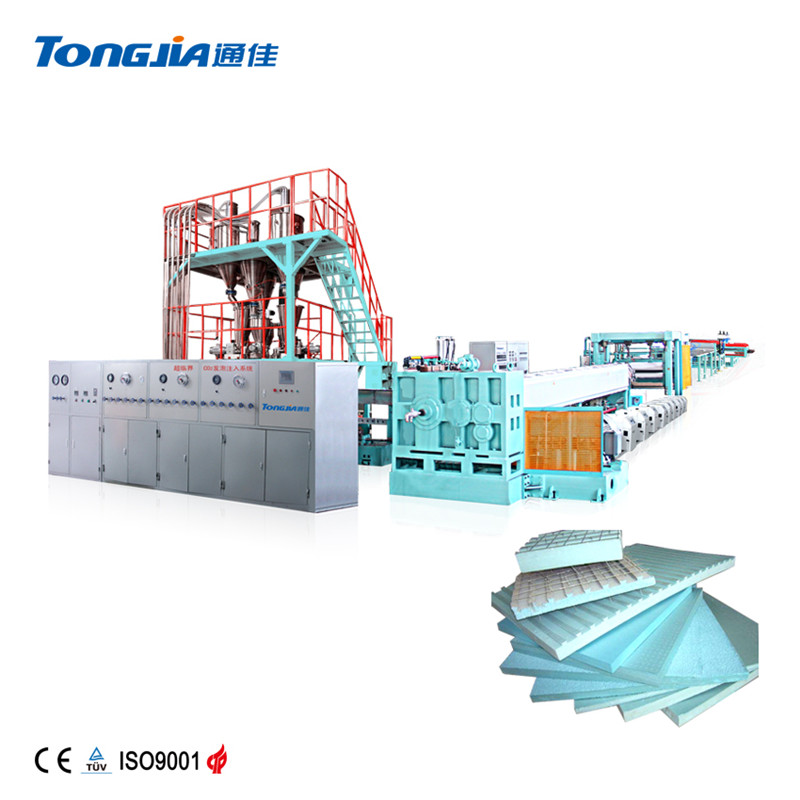

The CO2 XPS Foam Board Production Line is an advanced manufacturing system designed for the production of extruded polystyrene (XPS) foam sheets. Utilizing polystyrene combined with a unique foaming agent, this line produces high-quality heat insulation boards through a high-temperature extrusion process. Traditional methods often relied on fluorine-hydrogen chloride (HCFC) as a foaming agent, which has been gradually restricted due to its ozone-depleting potential as per the Montreal Treaty. Our technology offers a revolutionary solution by utilizing CO2, effectively eliminating the use of HCFCs and ensuring an eco-friendly, sustainable production process.

Shandong Tongjia Machinery Co., Ltd. has engineered this production line to meet diverse customer needs. The equipment supports various foaming agents, allowing for increased versatility and efficiency. With its fully automated control system managed by a central computer, the production process is streamlined, ensuring precision and intelligence in manufacturing.

Specifications

| Model | JG-XPS75P/170 | JG-XPS75P/200 | JG-XPS85P/250 | JG-XPS95P/300 | ||||

|---|---|---|---|---|---|---|---|---|

| Screw dia. | Ø75 | Ø170 | Ò75 | Ò200 | Ò250 | Ò95 | Ò300 | |

| Heating power (app.) | 70 KW | 96 KW | 75 KW | 100 KW | 75 KW | 100 KW | 110 KW | 150 KW |

| Driving motor power | 90 KW | 90 KW | 110 KW | 110 KW | 160 KW | 160 KW | 220 KW | 200 KW |

| Thickness of board | 20-100 mm | 20-120 mm | 20-100 mm | 20-150 mm | ||||

| Width of board | 600,900,1220 mm | 600,900,1220 mm | 600,900,1220 mm | 600,900,1220 mm | ||||

| Output (app.) | 350-500 kg/h | 500-700 kg/h | 500-700 kg/h | 800-1000 kg/h | ||||

| Installed capacity (app.) | 360 KW | 470 KW | 570 KW | 750 KW | ||||

| Dimensions (app.) | 45 × 10 × 4 m | 65 × 12 × 4 m | 75 × 13 × 4 m | 80 × 15 × 5 m | ||||

| Total weight (app.) | 30 T | 40 T | 50 T | 55 T |

Additional Information

- Environmentally friendly production process.

- Fully automated and intelligent control system.

- Customizable options for various foaming agent requirements.