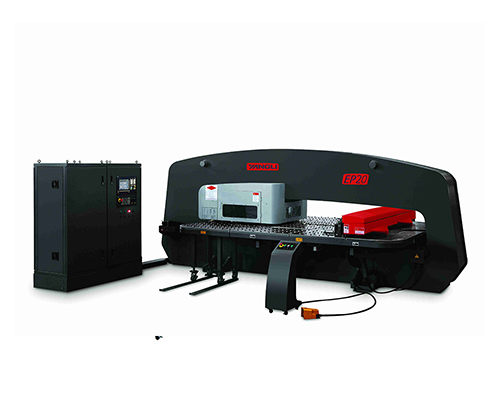

OEM ODM EP20 series CNC turret punchig machine

Description

The EP20 series CNC turret punching machine is engineered for precision and efficiency in metalworking. Its closed wide type frame undergoes a tempering treatment to eliminate stress and ensure stability. The streamlined arc body not only looks aesthetically pleasing but also contributes to its robust design.

This machine features a side positioning and sleeve-type thick turret, offering exact positioning, excellent guidance, and high accuracy. The adjustable clearance worm and worm gear mechanism, coupled with a rotary station, enhances operational precision.

The EP20 is equipped with a servo press and crankshaft-link drive mechanism, providing stable performance, high speed, and a quiet operation. It achieves energy savings of up to 60%, making it environmentally friendly. Additionally, this model incorporates the advanced SIEMENS (German) FANUC Oip (Japan) CNC system, known for its powerful functionality and user-friendly interface.

Other notable features include a high-speed mute automatic lubrication system for the guide screw, international pneumatic and electrical components, and full automatic float type clamps that deliver high performance. The stainless bolster with steel ball and brush ensures enhanced durability and functionality, making the EP20 an ideal choice for demanding manufacturing environments.

Specifications

| Feature | Description |

|---|---|

| Frame Type | Closed wide type with tempering treatment |

| Body Design | Streamline arc body |

| Turret Type | Side positioning and sleeve type thick turret |

| Mechanism | Clearance adjustable worm and worm gear with rotary station |

| Drive Mechanism | Servo press and crankshaft-link |

| Energy Saving | Up to 60% |

| CNC System | SIEMENS (Germany) FANUC Oip (Japan) |

| Lubrication System | High-speed mute automatic lubrication guide screw |

| Clamps | Full automatic float type clamps |

| Bolster Material | Stainless steel with steel ball and brush |

Additional Information

- High accuracy and performance suitable for various applications.

- Ideal for manufacturing environments requiring efficiency and precision.

- Easy to operate with advanced CNC technology.