Description

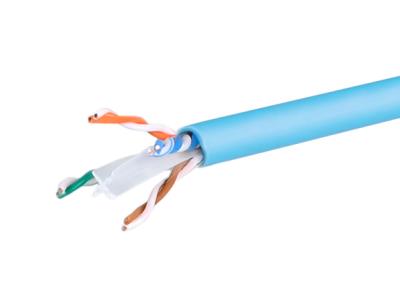

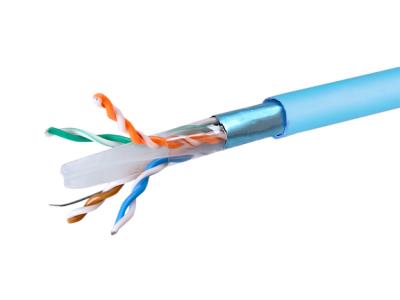

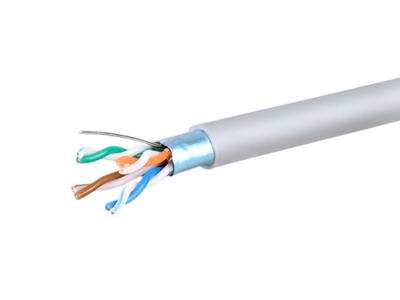

The CAT6 high-speed cable is engineered for superior performance, utilizing high-quality copper materials that deliver exceptional tensile properties and robust electrical resistance. This state-of-the-art cable features optimized pitch technology and advanced production processes, ensuring maximum efficiency and reliability. It has undergone rigorous testing by an authoritative tripartite organization, supporting a bandwidth of up to 250MHz. Fully compliant with REACH and RoHS requirements, this cable is designed for both safety and performance, making it an ideal choice for high-speed networking.

Specifications

| Attribute | Details |

|---|---|

| Conductor | Solid bare copper |

| Insulation Material | High density polyethylene |

| Insulation Diameter | 1.02 ± 0.03mm (unshielded ordinary) 1.02 ± 0.05mm (unshielded sawtooth type) 1.09 ± 0.03mm (shielded) |

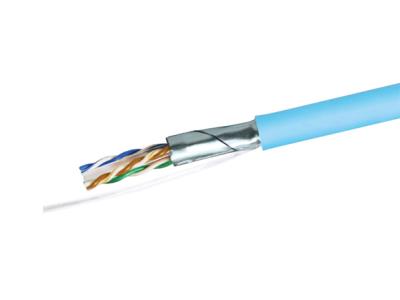

| Single Layer Total Shielding | Aluminum foil (shielding) |

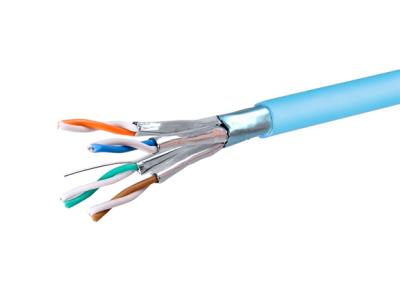

| Double Layer Total Shielding | Aluminum foil + tinned copper, coverage rate ≥40% (braided shielding part) |

| Sheath Diameter | 6.3 ± 0.4mm (unshielded ordinary) 7.1 ± 0.4mm (unshielded sawtooth type) 7.4 ± 0.4mm (F/UTP shielded) 7.8 ± 0.3mm (SF/UTP shielded) |

| Sheath Material | PVC or LSZH low-smoke halogen-free (according to different jackets) |

| Working Temperature | -30 ℃ to 50 ℃ (LSZH) -20 ℃ to 50 ℃ (PVC) |

| Tensile Strength Before Aging | ≥13.5Mpa (PVC) ≥10.0Mpa (LSZH) |

| Elongation Before Aging | ≥150% (PVC) ≥125% (LSZH) |

| Aging Time | 100 ℃ × 24 hours × 7 days |

| Tensile Strength After Aging | ≥12.5Mpa (PVC) ≥8Mpa (LSZH) |

| Elongation After Aging | ≥125% (PVC) ≥100% (LSZH) |

| Cold Bending | 8 times the outer diameter of the cable without cracking (-20 ± 2 ℃ × 4 hours) |

Additional Information

- Reference Standards: UL444, UL1581, UL1666, IEC60332-1, IEC60332-3-24, EN50399

- Test Standards: ISO / IEC11801, ANSI / TIA-568-C.2