Description

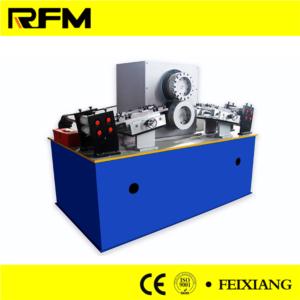

The EPS Sandwich Plate Production Line is a highly efficient and versatile roll forming machine designed for producing high-quality EPS sandwich panels. This advanced machinery utilizes galvanized steel or aluminum materials, with thicknesses ranging from 0.3mm to 0.8mm and yield strengths between 235 to 450 MPa. The machine is capable of producing panels with widths of 1000mm or 1200mm and thicknesses from 50mm to 250mm, making it suitable for various applications in the construction industry.

Equipped with a robust frame made of welded steel plates and a memorial arch design, this production line features a main forming machine, hydraulic pump, and cutting device, all efficiently coordinated by a control panel. The system operates smoothly with a speed of up to 4 m/min and requires a power supply of 380V 50Hz 3-phase, ensuring reliability and optimal performance.

Specifications

| Attribute | Details |

|---|---|

| Brand | Feixiang |

| Model Number | FX-E |

| Machine Size | 4500*8000*5000 mm |

| Weight | 15.0 T |

| Voltage Requirement | 380V 50Hz 3P or as requested |

| Working Speed | 0-4 m/min |

| Labor Requirement | 8-12 workers |

| Machine Base | Steel plate welded |

| Frame | Memorial arch frame or middle plate |

| Forming Stations | 14 steps |

| Roller Material | 45# steel with quenching |

| Shaft | 45# steel, diameter 70mm |

| Transportation | Chain |

| Motor | Siemens, 5.5 kW |

| Pump | Yuken 4 kW |

| Cutter | Cr12 |

| Composite Material | Foam, rock wool, PU |

| Compound Machine Power | 32.0 kW |

Additional Information

Delivery time is 45 days after receipt of the deposit. The product comes with a 2-year warranty and after-sales service, including 24/7 online support and on-site engineer service. In the event of an epidemic, machine adjustments can be conducted via video call.