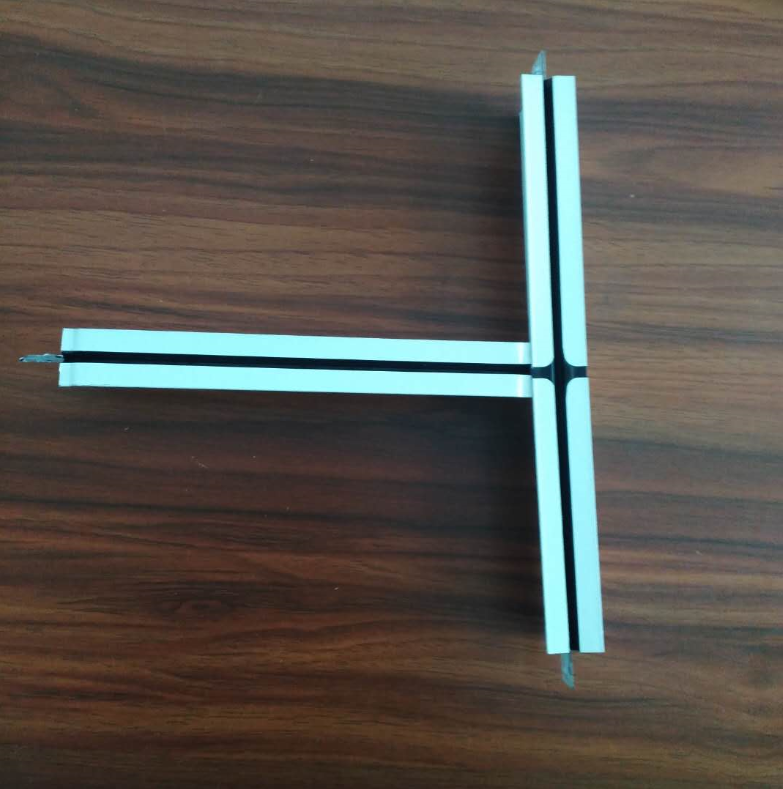

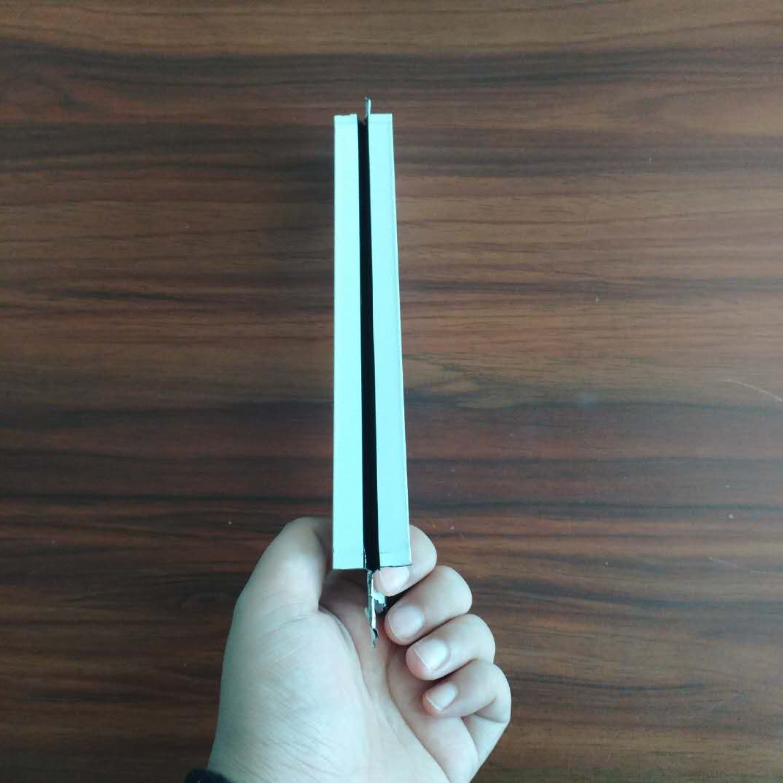

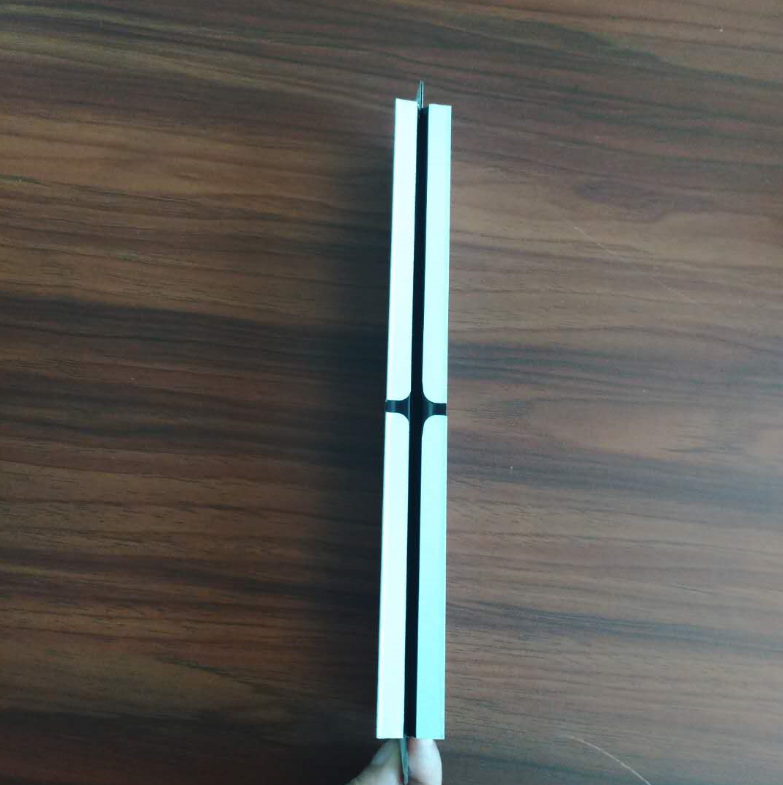

Description

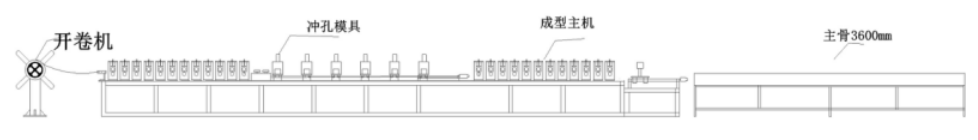

The FUT ceiling production line is designed for efficiency and precision in manufacturing ceiling panels. This advanced production line includes essential components such as a 3 tons manual decoiler, a roll forming machine, and a hydraulic stop cutting system, ensuring high-quality output with minimal downtime. It features a user-friendly PLC control system from the Xinjie brand, optimizing the production process for ease of use and reliability. The line is equipped with a Huade brand 5KEDC24V solenoid valve and supporting motor, delivering consistent performance and durability.

Specifications

| Name | Description |

|---|---|

| 3 tons manual decoiler | Capacity: 3 tons, Manual |

| Roll forming machine | |

| Hydraulic Stop Cutting | Material: Cr12 |

| Punching machine | Punching mould: 1 set for side holes |

| Collection table | 3600mm, welded 40*60 steel square tubes |

| Hydraulic station | 5KEDC24V solenoid valve (Huade brand) and supporting motor |

| PLC brand | Xinjie brand |

| Machine body plate | Thickness: 23mm |

| Rollers | 22 steps/Cr12 with heat treatment HRC58-62, symmetry in the range of 0.05mm |

| Shaft | 45# steel with heat treatment/Φ40 |

| Chain Driven | |

| Torrrist stand structure | Plate 35mm, CNC equipment control accuracy within 0.1 mm |

| Punching mould | 5 sets, Material: SKD11 with heat treatment |

| Main power | 7.5kw |

| Speed | 30m/min |

Additional Information

- Machine includes:

- 3 tons manual decoiler

- Main forming part (with 6 pairs of punching moulds)

- Hydraulic stop cutting system

- Punching machine (One pair of punching mould for side holes)

- Hydraulic station

- PLC control system