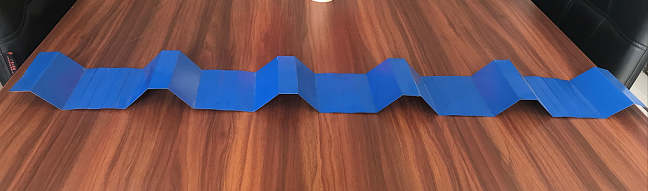

Description

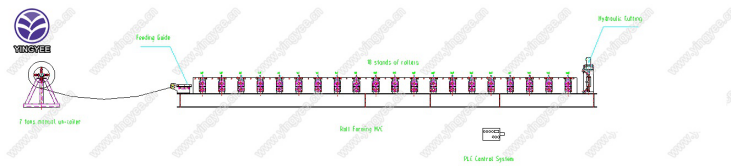

The IBR/trapezoid roof sheet roll forming machine is designed for efficiency and precision in metal sheet production. Capable of operating at a speed of 30 meters per minute, this advanced machine comes equipped with an electric cutter, making it a reliable choice for manufacturers looking to streamline their roofing sheet fabrication process. Constructed using high-quality materials, this machine ensures durability and performance, suitable for working with various materials including PPGI, GI, and Aluminium.

Key components of the machine include a manual coiler, adjustable input leveling equipment, a main roll forming machine with chromed plates, and a hydraulic cutting system. The PLC control system enhances operational efficiency, allowing for precise control of the production process.

Specifications

| Feature | Details |

|---|---|

| Matching Material | PPGI/GI/Aluminium |

| Material Thickness | 0.2-0.8 mm |

| Power | 7.5 kW |

| Forming Speed | 30 m/min |

| Width of Plates | According to drawings |

| Input Leveling Equipment | Adjustable |

| Roll Stations | 22 |

| Shaft Material and Diameter | 45# Steel, ¢75 mm |

| Tolerance | 10 m ± 1.5 mm |

| Way of Drive | Chain driven |

| Controlling System | PLC |

| Voltage | Depends on client |

| Material of Forming Rollers | 45# Steel, heat treatment and chromed |

| Side Plate | Steel plate with Chromed |

| Size | Length: 6.7 m, Weight: 5 tons |

Additional Information

- Hydraulic cutting system included for precise cuts.

- PLC control system ensures ease of operation and efficiency.