Description

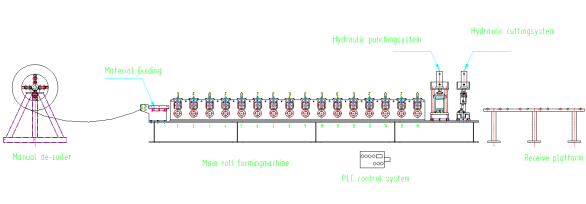

The glazed tile roof sheet roll forming machine is a state-of-the-art solution designed for producing high-quality glazed tiles efficiently. This machine is engineered to handle a range of materials with a thickness between 0.2 to 0.8 mm, enabling versatility for different roofing needs. Featuring a robust main motor with a power of 7.5 kW and a hydraulic station of 4 kW, it ensures smooth and efficient operation. The machine is capable of running at a speed of 7 meters per minute, which includes both punching and cutting processes. With 22 rollers made from durable 45# chrome-plated material, it guarantees precision and longevity in production. The machine’s design incorporates a PLC control system for enhanced automation and ease of use, making it an ideal choice for manufacturers looking to streamline their roof sheet production.

Specifications

| Attribute | Details |

|---|---|

| Material Thickness Range | 0.2 – 0.8 mm |

| Main Motor Power | 7.5 kW |

| Hydraulic Station Power | 4 kW |

| Speed | 7 m/min (including punching and cutting) |

| Quantity of Rollers | 22 |

| Material of Rollers | 45# with chromed finish |

| Shaft Material and Diameter | ¢75 mm, 45# forged steel |

| Body Material | 350H |

| Tolerance | 10m ± 1.5 mm |

| Way of Drive | Gearbox |

| Control System | PLC |

| Cutter Blade Material | Cr12 mould steel with quenched treatment 58-62℃ |

| Voltage | 380V / 3 phase / 50 Hz |

| Machine Size | Length: 8 – 9 m |

| Weight | 10 tons |

Additional Information

For optimal performance and longevity, it is recommended to regularly maintain the machine, ensuring that all components are functioning correctly and lubricated as necessary. Proper handling and operation according to the manufacturer’s guidelines will maximize efficiency and output quality.