Description

The 1000tpd cement production line is a comprehensive and efficient solution designed to optimize the cement manufacturing process. This EPC project encompasses a wide range of services, including process design, equipment supply, civil engineering, installation, commissioning, trial operation, and final delivery. The facility is equipped with advanced mechanical systems for limestone and clay crushing, raw material batching, grinding, and waste gas treatment, ensuring a seamless production flow from raw material handling to final cement packaging.

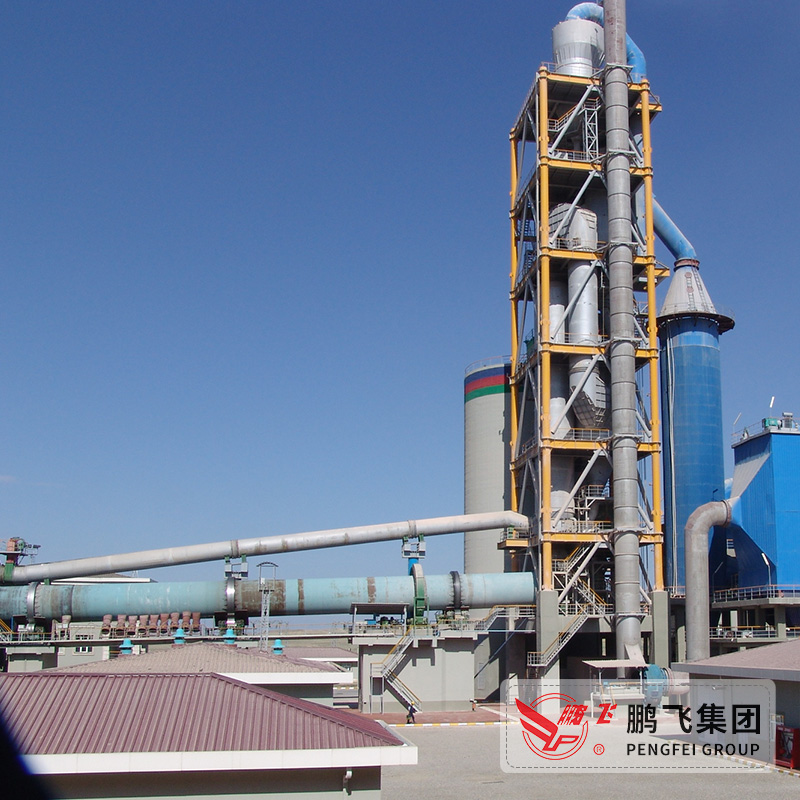

Utilizing a dry production method, this line effectively minimizes heat consumption while maximizing output. The production process begins with the crushing of limestone and clay, followed by precise batching and grinding before the raw materials are fed into a cement rotary kiln for calcination. The resulting clinker is then mixed with gypsum and ground into cement, ready for shipment in both bagged and bulk formats. This well-structured production line not only meets high standards of efficiency but also adheres to environmental regulations regarding dust emissions and energy consumption.

Specifications

| No. | Department | Main Equipment | Plan | Qty |

|---|---|---|---|---|

| 1 | Limestone | Single-stage hammer crusher Feeding size: ≤600×600×600mm Crushing system capacity: 120t/h Finished product fineness: 90% ≤25mm |

6d/w×7h/d | 1 |

| 2 | Sand crushing and conveying | High efficiency crusher Feeding size: ≤215mm Crushing system capacity: 50t/h Finished product fineness: 90% ≤20mm |

1d/w×7h/d | |

| 3 | Raw material grinding | Circled ball mill Φ 3.5×8m Feeding size: ≤25mm Finished product fineness: <R12% @ 80μ Capacity: 50 t/h |

7d/w×20h/d | 1 |

| 4 | Clinker firing | Five-stage cyclone, preheater + precalciner Rotary kiln: Φ3.2×50M Heat consumption: ≤950kCal/kg Capacity: 800t/d (33.3t/h) |

7d/w×24h/d | 1 |

| 5 | Cement grinding | Ball mill: circled Φ3.4×11M Capacity: 45 t/h PC32.5 Power: 1600 Kw |

7d/w×22h/d | 1 |

| 6 | Cement packing | 8-spouts rotary packing machine Capacity: 100t/h |

6d/w×12h/d | 1 |

Additional Information

For optimal performance, regular maintenance and monitoring of the equipment are recommended to ensure longevity and efficiency. This production line is designed to meet high operational standards while minimizing environmental impact.