Description

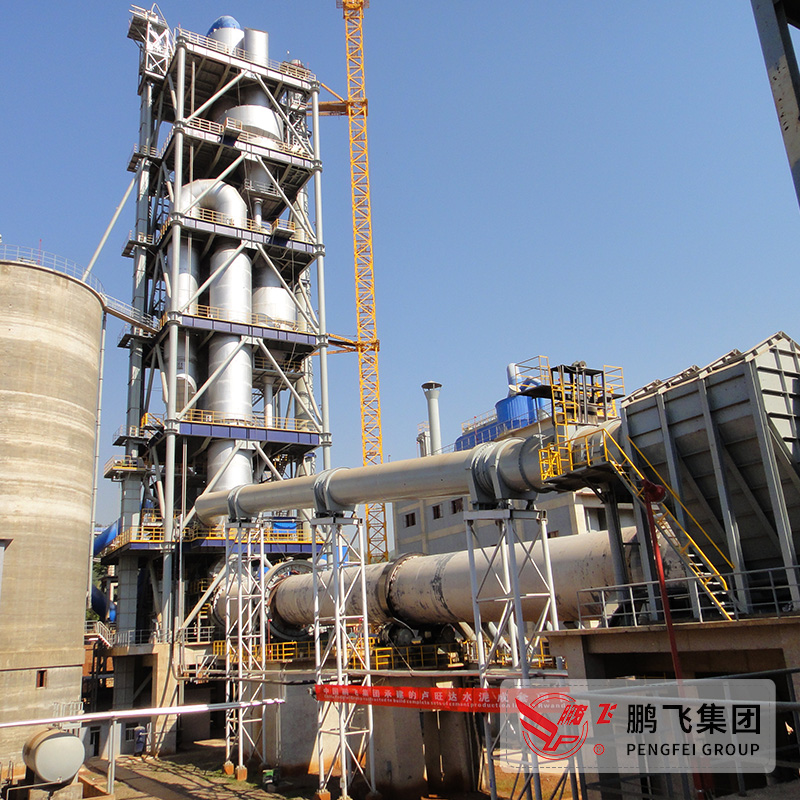

The 1500t/d cement production line is a comprehensive solution designed for efficient cement manufacturing. This project encompasses everything from process design and equipment supply to installation and commissioning, ensuring a seamless operational experience. The line features advanced mechanical equipment including limestone crushing, clay processing, and raw material grinding, all integrated with robust waste gas treatment systems.

Key processes involve the crushing of limestone and clay, followed by their proportioning and milling into raw materials, which are then calcined in a rotary kiln. The production line also includes cement grinding, storage, packaging, and bulk loading systems. This state-of-the-art facility utilizes a dry cement production process, offering significant advantages such as reduced heat consumption and enhanced efficiency.

Specifications

| No. | Name of Workshop | Main Equipment | Working Programme (d/w×h/d) | Qty |

|---|---|---|---|---|

| 1 | Limestone | Single hammer crusher Feed size: ≤800×800×1000mm Crushing system capacity: 350 t/h Product size: 90% ≤25mm |

6d/w×7h/d | 1 |

| 2 | Sandstone crushing and conveying | High efficiency crusher Feed size: ≤215 mm Crushing system capacity: 50 t/h Product size: 90% ≤20 mm |

1d/w×7h/d | |

| 3 | Limestone prehomogenizing and conveying | Stacker Capacity: 350 t/h |

6d/w×7h/d | 1 |

| Reclaimer Capacity: 150 t/h |

7d/w×20h/d | 1 | ||

| 4 | Raw peat Prehomogenizing and conveying | Feed hopper with extractor Peat extractor: 80 t/h Peat conveying: 30 t/h |

7d/w×4h/d | 1 |

| 5 | Raw material grinding | Closed circuit Ball mill Φ 4.0X9 m (precrushing/drying) Feed size: ≤25mm Product fineness: Product moisture: <1% Capacity: 120 t/h |

7d/w×20h/d | 1 |

| 6 | Peat grinding | Closed circuit ball mill Φ 2.6x(5.25+2.25)m Feed size: ≤25mm Product fineness: Product moisture: <1.5% Capacity: 13-15 t/h |

6d/w×20h/d | 1 |

| 7 | Clinker burning Temperature @ cyclones outlet ≤350±10°C |

Five-stage cyclones, Preheater + precalciner: C1:2-Φ5450 mm C2:1-Φ5450 mm C3:1-Φ5450 mm C4:1-Φ5700 mm C5:1-Φ5700 mm Precalciner: 1-Φ 4600 mm Temperature @ cyclones outlet ≤350±10°C Rotary kiln: Φ3.5X54m Heat consumption: ≤840kcal/kg Capacity: 1500t/d (62.5t/h) Power: 220 kW, DC Fuel: Fuel oil and peat Grate cooler: mechanical drive Bed area: 39 m2 Capacity: 1500t/d |

7d/w×24h/d | 1 |

| 8 | Cement grinding | Ball mill: Two closed circuit Φ3.2×13m. Product size: Power: 2 × 1600 kW |

7d/w×22h/d | 2 |

| 9 | Cement bagging | Two 8 spouts rotating packers Capacity: 2×100 t/h One bulky station provided. |

6d/w×12h/d | 2 |

Additional Information

For optimal performance, ensure regular maintenance of all equipment, especially during peak operation periods. The facility is designed to minimize energy consumption, making it environmentally friendly while maintaining high productivity standards.