Description

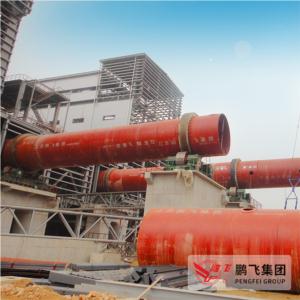

The rotary kiln is a crucial industrial equipment used for the calcination of materials. Its body is constructed from high-quality steel plates, featuring a refractory lining that ensures durability and efficiency. The kiln operates at a slight horizontal angle, allowing materials to roll and move axially as they undergo thermal processing. Each support device is reinforced with triple wheel belts, while a gear ring encircles the inner cylinder, ensuring smooth operation. The kiln’s design includes a meshing pinion that transmits power from the main drive motor to the rotary kiln, facilitating consistent and reliable performance.

The working principle of the rotary kiln involves material being fed into the kiln from the upper end. As the cylinder rotates, materials roll circumferentially while also moving axially, completing the necessary decomposition and calcination processes through physical and chemical changes. The fuel is injected from the kiln head, with combustion gases exiting after exchanging heat with the materials, ensuring optimal thermal efficiency.

The rotary kiln comprises several key components, including the cylinder and kiln lining, wheel belt, support device, drive device, kiln head cover, burner, smoke chamber, heat exchange device, and feeding equipment.

Specifications

| Component | Description |

|---|---|

| Cylinder and Kiln Lining | High-quality steel plates with refractory lining |

| Wheel Belt | Supports the rotating kiln body |

| Support Device | Reinforced with three wheel belts |

| Drive Device | Transmits power from the motor to the kiln |

| Burner | Injects fuel for combustion |

| Heat Exchange Device | Facilitates heat transfer between materials and exhaust gases |

Additional Information

Routine inspections are vital for maintaining the rotary kiln’s performance. Inspections should include:

- Drive device inspection

- Wheel belt and support device inspection

- Kiln cylinder inspection

- Sealing device inspection