Description

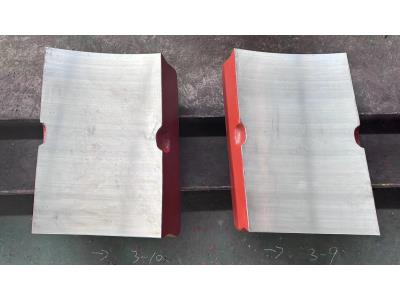

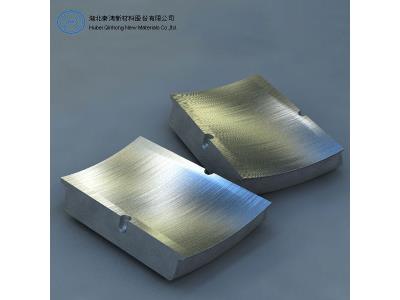

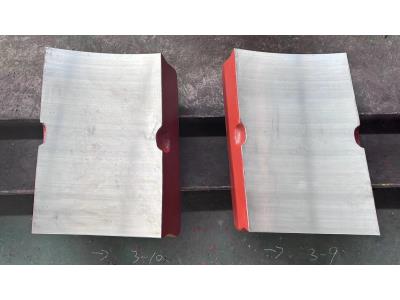

The ATOX series roller segment is expertly crafted to meet the rigorous production standards of EN 12513, ASTM A532, and GB/T8263. Made from high chromium cast iron, nickel cast iron, and advanced composite wear-resistant materials, these segments boast a hardness greater than 60HRC, ensuring exceptional durability and performance.

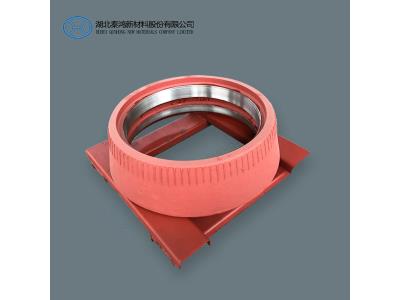

Utilizing innovative processes in material research and development, along with advanced heat treatment techniques, our wear-resistant components offer a service life that exceeds similar domestic products by over 10%. Not only do they provide superior cost performance compared to imported parts, but they also encompass a wide range of models including ATOX, LM, MPS, RM, CKP, MLS, MPF, TRM, HRM, and ZGM types.

Each roller and lining component is meticulously engineered for precision, featuring an integral assembly process that enhances installation accuracy and minimizes mill vibrations. This reduces damage to the grinding roll body and extends the life of wear-resistant parts, making the ATOX series an ideal choice for high-efficiency milling operations.

Specifications

| Standard Compliance | EN 12513, ASTM A532, GB/T8263 |

|---|---|

| Material | High Chromium Cast Iron, Nickel Cast Iron, Metal Composite Ceramics |

| Hardness | > 60 HRC |

| Service Life | Over 10% longer than domestic alternatives |

| Models Available | ATOX, LM, MPS, RM, CKP, MLS, MPF, TRM, HRM, ZGM |

Additional Information

For optimal performance and longevity, it is recommended to follow proper installation procedures and routine maintenance checks. This ensures the wear-resistant parts maintain their integrity and efficiency throughout their service life.