Description

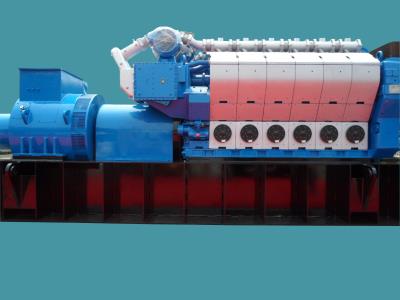

The 190 series mash gas engine and gensets from CNPC Chai Gas are at the forefront of coal bed methane power generation. Since their inception in 2003, these innovative products have evolved through significant research and development efforts, establishing partnerships with key coal mining research institutes. The engines are designed to operate efficiently across a wide range of methane concentrations, from 8% to 60%, making them versatile for various applications. With advanced gas machine control technology and thin combustion theory, these engines achieve outstanding performance, fuel economy, and reliability, meeting international standards.

These engines and gensets are distributed across 13 major coal-producing areas, with over 500 units sold in the Shanxi market alone. Their robust features include an intelligent management system, automatic air-fuel ratio regulation, and online maintenance technology, ensuring continuous operation and minimal downtime.

Specifications

| Engine Series | Engine Model | Cylinders & Arrangement | Cylinder Bore (mm) | Piston Bore (mm) | Rated Power (kW) | RPM (r/min) | Total Piston Displacement (L) | Heat Consumption Rate (kJ/kW.h) | Lub. Oil Consumption Rated (g/kW.h) | Starting Mode |

|---|---|---|---|---|---|---|---|---|---|---|

| 190 High Concentration Gas Engine (550-1200KW) | G12V190ZLW-2 | 12 cylinders V type | 190 | 210 | 550 | 1000 | 71.5 | ≤11000 | ≤0.8 | Electrical starting |

| H16V190ZLW-2 | 16 cylinders V type | 215 | 1200 | 97.53 | ≤9500 | ≤0.6 | Electrical starting/Air Starting | |||

| 190 Low Concentration Gas Engine (660-1200KW) | G12V190ZLWD4-2 | 12 cylinders V type | 210 | 660 | 71.5 | ≤11000 | ≤0.8 | Electrical starting | ||

| H16V190ZLWD-2 | 16 cylinders V type | 215 | 1200 | 97.53 | ≤9500 | ≤0.6 | Electrical starting/Air Starting | |||

| L20V190ZLWd-2 | 20 cylinders V type | 255 | 1600 | 144.6 | ≤9000 | ≤0.6 | Air Starting | |||

| Gensets Series | Genset Model | Engine Model | Alternator Model | Power (kW) | RPM (r/min) | Rated Voltage (V) | Frequency (Hz) | Power Factor | Dimension (mm) | Weight (kg) |

| 190 High Concentration Gas Gensets (500-1600KW) | 500GF-WK | G12V190ZLW-2 | 1FC Series | 500 | 1000 | 400 | 50 | 0.8 | 5120×2040×2776 | 13800 |

| 1000GF-W | H16V190ZLW-2 | 1FC Series | 1000 | 400 | 6760×2180×2540 | 25000 | ||||

| 1000GF9-WK | H16V190ZLW-2 | JFG Series | 1000 | 10500 | 6760×2180×2540 | 25000 | ||||

| 190 Low Concentration Gas Gensets (500-1500KW) | 500GF-WK2 | G12V190ZLWD2-2 | 1FC Series | 500 | 400 | 5120×2200×2778 | 13800 | |||

| 600GF9-WDK | G12V190ZLWD4-2 | JFG Series | 600 | 10500 | 5120×2200×2778 | 13800 | ||||

| 1000GF-WK2 | H16V190ZLWD1-2 | 1FC Series | 1000 | 400 | 6760×2180×2540 | 25000 | ||||

| 1000GF9-WK1 | H16V190ZLWD1-2 | JFG Series | 1000 | 10500 | 6760×2180×2540 | 25000 | ||||

| 1500GF-WD | L20V190ZLWd-2 | 1500 | 6300 | 9093×3786×2786 | 28000 |