OEM ODM High Productivity Metal Surface Grinding Machines

Description

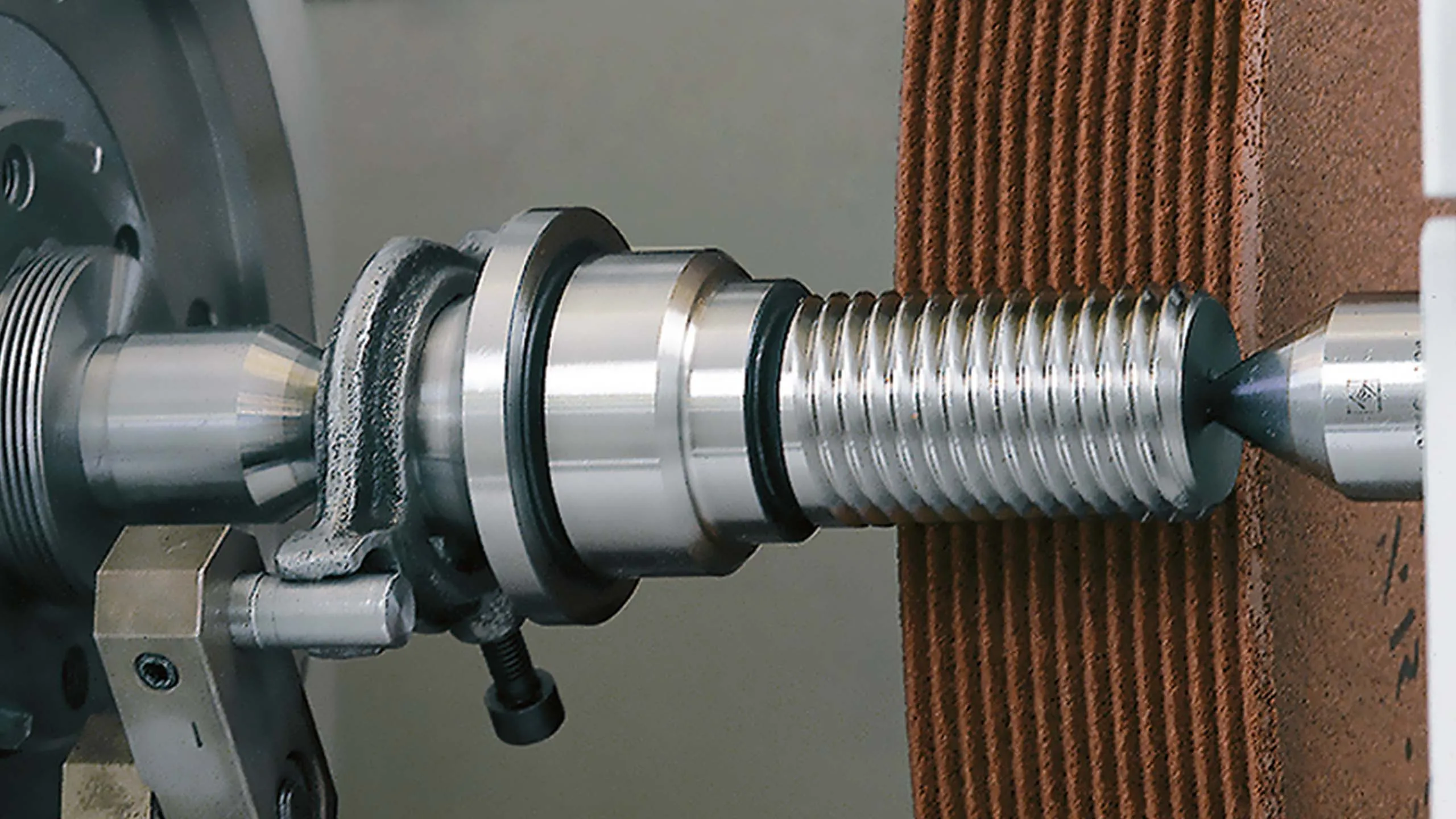

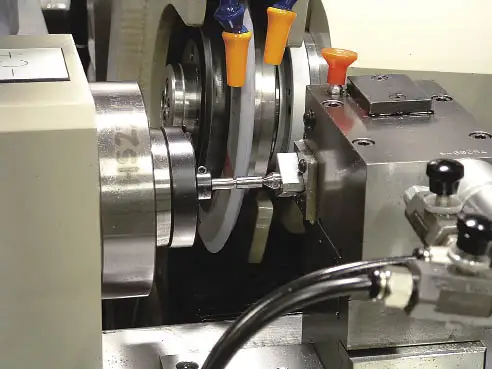

The High Productivity Metal Surface Grinding Machines are advanced tools specifically designed for precision thread processing. Utilizing a shaped grinding wheel as an abrasive tool, these machines ensure high efficiency and accuracy in metal surface grinding. Equipped with state-of-the-art technological features, these grinders not only enhance productivity but also provide a user-friendly programming experience.

Key Features:

- Electronic gearbox for easy programming and expanded lead range.

- 18000-line angle encoder and grating ruler for closed-loop control.

- High-precision rolling bearing support for spindle structure.

- Stepless speed regulation via inverter control.

- Automatic indexing of the workpiece through a numerical control system.

- Fully enclosed housing with an electrostatic air purifier for an optimal working environment.

Specifications

| Specification Model | S7432 Leadscrew Grinder | 17608 | 17609 | 17610 |

|---|---|---|---|---|

| Max. dia. x length of workpiece | mm | 320 x 1000 | 320 x 1500 | 320 x 2000 |

| Dia. ground (external/internal) | mm | 6-320/— | ||

| Max. length ground (external/internal) | mm | 1000/– | 1500/– | 1850/– |

| Lead of thread to be ground: metric | mm | 1-40 | ||

| Inch | t/in | 1-14 | ||

| Module | 1-16 | |||

| Screw Starts to be ground | No. | 1, 2, 3, 4, 5, 6, 8, 10, 12 | ||

| Max ball screw to be ground | mm | R10 | ||

| Center height | mm | 170 | ||

| Weight of workpiece | kg | 150 | ||

| Wheel spindle speeds | r/min | 1340, 1470 | ||

| Internal grinding spindle speeds | r/min | —— | ||

| Total motor power | kw | 7.1 | ||

| Machine weight | kg | 6350 | 6900 | 8700 |

| Overall dimensions (LxWxH) | mm | 3380x2010x1800 | 4350x2010x1800 | 5350x2010x1800 |

Additional Information

This machine is designed for high performance and durability, making it an ideal solution for businesses looking to enhance their metal processing capabilities. With a weight capacity of up to 150 kg for workpieces, it is suitable for a variety of applications. The advanced technology ensures consistent quality and precision, which is essential in the manufacturing industry.