Description

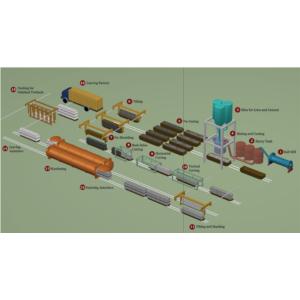

The Aluminum Alloy Cable Manufacturing Equipment is a comprehensive solution designed for the efficient production of aluminum alloy cables. This advanced setup includes various specialized machines that enhance the manufacturing process, ensuring high-quality output. Key features include:

- Rolling of Aluminum Alloy Rod: Continuous casting and rolling unit for aluminum and aluminum alloy.

- Single Wire Drawing: Φ 450 non-sliding drawing machine for precise wire shaping.

- Conductor Stranding: Equipped with JSH strand strander, JLK frame strander, and JGG tube strander for robust cable construction.

- Annealing: Dedicated annealing furnace for enhancing conductor quality.

- Insulation: SPV extruder for effective insulation application on conductors.

- Cable Forming: CPD winch, CGB bow, and CLY cradle machines for various cable forming needs.

- Interlocking Armor: KRH interlocking armor machine for added durability.

Specifications

| Feature | Description |

|---|---|

| Rolling Unit | ULL + ZRL aluminum and aluminum alloy continuous casting and rolling unit |

| Single Wire Drawing Machine | LFDL Φ 450 non-sliding aluminum alloy drawing machine |

| Conductor Stranding Machines | JSH strand strander, JLK frame strander, JGG tube strander |

| Annealing Furnace | Specialized furnace for aluminum alloy conductors |

| Insulation Extruder | SPV extruder for insulation application |

| Cable Forming Machines | CPD winch, CGB bow, CLY cradle cable forming machines |

| Interlocking Armor Machine | KRH interlocking armor machine |

Additional Information

For optimal performance, it is recommended to regularly maintain all equipment and adhere to safety guidelines during operation. Proper training for operators is essential to ensure the effective use of each machine in the manufacturing process.