#### **Description**

The corrugated iron sheet making aluzinc roll forming machine is an advanced and automated solution designed for efficiently producing high-quality corrugated sheets. This machine excels in processing color steel plates, making it ideal for various construction and roofing applications. With a robust construction and user-friendly operation, it offers significant productivity, producing sheets at a rate of 8-12 meters per minute.

#### **Specifications**

| Feature | Details |

|---|---|

| Suitable to Process | Color steel plate |

| Width of the Plate | 1000mm |

| Thickness of the Plate | 0.3-0.8mm |

| De-coiler | Manual, can load 5 tons raw material |

| Rollers for Forming | 14 rows |

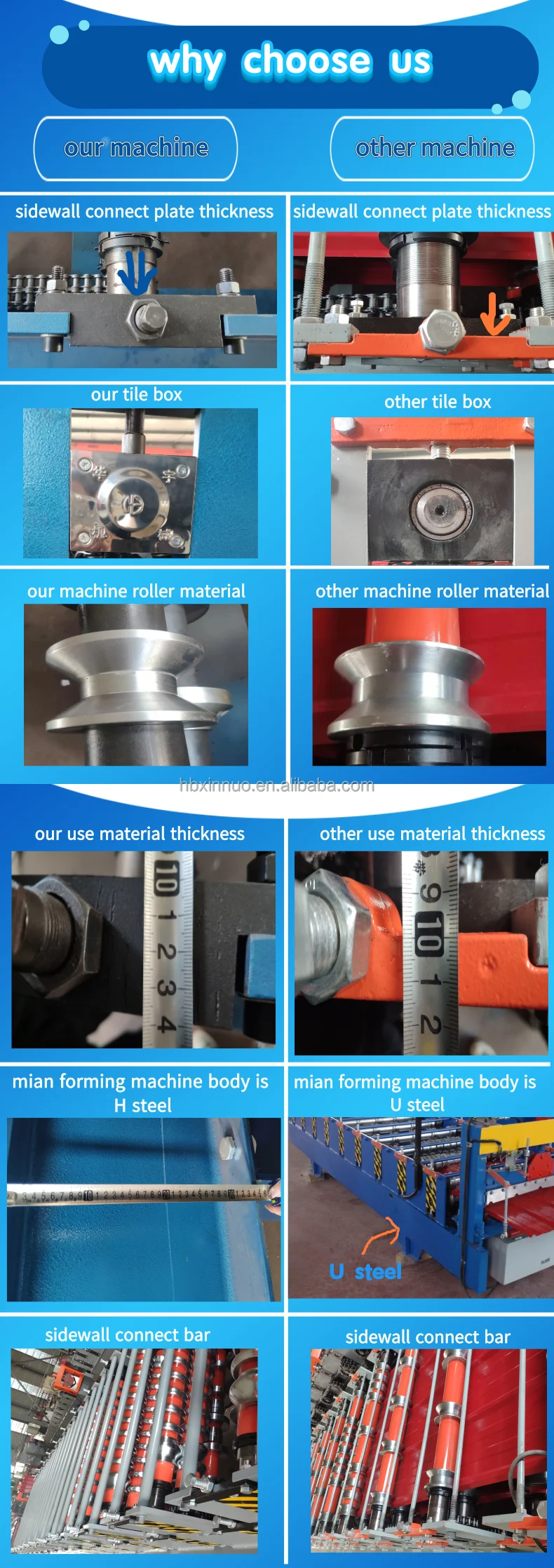

| Diameter of the Roller | 80mm |

| Rolling Material | Carbon Steel 45# |

| Main Motor Power | 4kw |

| Productivity | 8-12m/min |

| Cutting Method | Hydraulic mould cutting |

| Material of the Cutting Blade | Cr12 |

| Hydraulic Cutting Power | 3kw |

| Processing Precision | Within 1.00mm |

| Control System | Delta PLC control |

| Side Panel of Machine | 14mm |

| Main Structure of the Machine | 300 H steel |

| Weight | About 4.6T |

| Dimensions | 7.5*1.6*1.2m |

| Voltage | 380V 50Hz 3 phases (changeable as needed) |

| Certificate | CE/ISO |

#### **Additional Information**

**Packaging Details:**

Main machine is nude, and the computer control box is packed with a wooden frame.

**Delivery Detail:**

20 days.