OEM ODM Z-lock sandwich wall panel production line sheet forming roll machine drywall manufacturin

Description

The Z-lock sandwich wall panel production line is a state-of-the-art machine designed for the efficient manufacturing of drywall panels. This automatic roll forming machine specializes in creating EPS and rock wool sandwich panels, making it a vital addition to any construction or manufacturing facility. With its advanced PLC control system, this machine ensures high precision and stability during operation, allowing for a streamlined production process that can handle various materials.

Key features include the ability to process coil materials such as EPS, rock wool, and glass silk floss, with a plate thickness ranging from 0.3mm to 0.8mm. The machine boasts a core thickness capability of 20mm to 300mm and a production capacity of 2-4.5m/min, depending on the adhesive used. Additionally, it operates with a total power of approximately 30KW and has a considerable weight of 25 tons, ensuring robust performance.

The overall dimensions of the production line are approximately 35000mm in length, 2500mm in width, and 2600mm in height, making it a substantial yet efficient solution for sandwich panel production.

Specifications

| Attribute | Details |

|---|---|

| Coil Material | EPS, Rock Wool, Glass Silk Floss |

| Plate Thickness | 0.3 – 0.8 mm |

| Core Thickness | 20 – 300 mm |

| Production Capacity | 2 – 4.5 m/min |

| Total Power | About 30 KW |

| Weight | 25 tons |

| Dimensions | 35000 mm × 2500 mm × 2600 mm |

Additional Information

Processing Technique: The machine utilizes a composite decoiler followed by roll forming, a laminating system (including ribbon, gelatinizing, heating up, compounding, crimping, notching, and edge trimming), cutting system, and a runout table.

Terms of Payment: 30% of the total contract value as a down payment via T/T, with the remaining 70% due after inspection at the seller’s factory before delivery.

Delivery: 60 days after receipt of advance payment.

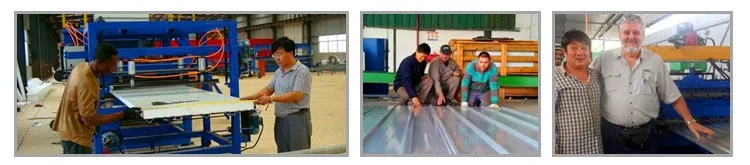

Service: Technicians will be sent to assist with setup; costs for travel and accommodation will be borne by the buyer.

Warranty: 12 months limited warranty; parts are free during warranty, but shipping fees are the buyer’s responsibility.

Note: Custom designs and adjustments to plate types are available upon request.