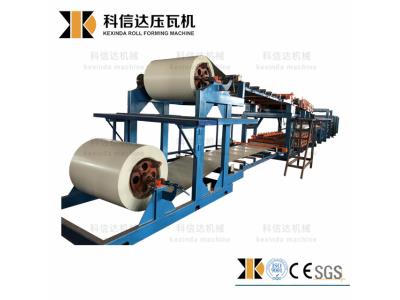

Sandwich Panel Roll Forming Machine

Inquire NowDescription

The Sandwich Panel Roll Forming Machine is a highly efficient production line specifically designed for producing insulation composite boards. This advanced machine features a stepless speed regulation system, allowing it to produce corrugated composite panels in a single operation. It has become an essential tool for fabricating roof and wall panels in various buildings, including plants and warehouses. With its robust construction and innovative technology, this machine ensures high-quality output while maximizing operational efficiency.

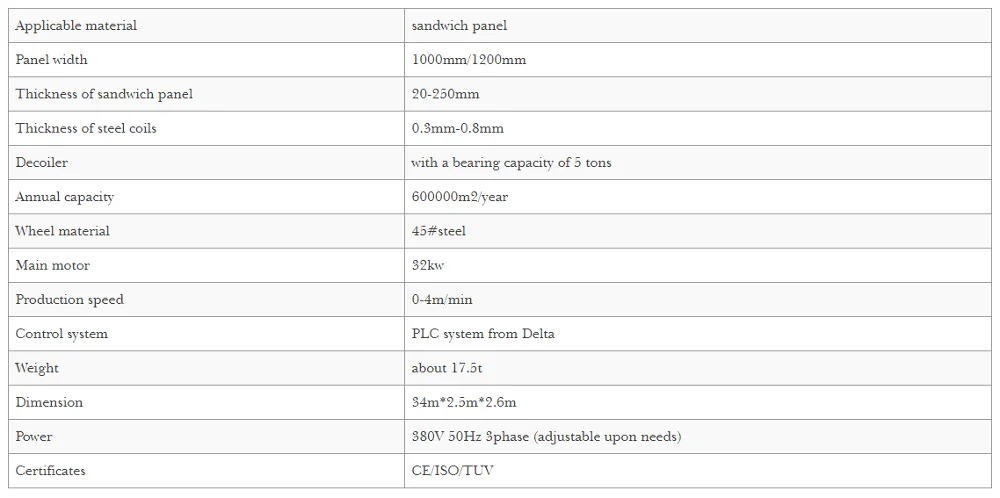

Specifications

| Attribute | Details |

|---|---|

| Motor Power | 4 kW |

| Production Speed | 6 m/min (variable 0-6 m/min) |

| Installed Capacity | 34 kW |

| Total Weight | 17.5 t |

| Panel Thickness | 50 mm to 250 mm |

| Dimensions | 12500 mm x 2200 mm x 2800 mm (16000 mm for rock wool boards) |

Additional Information

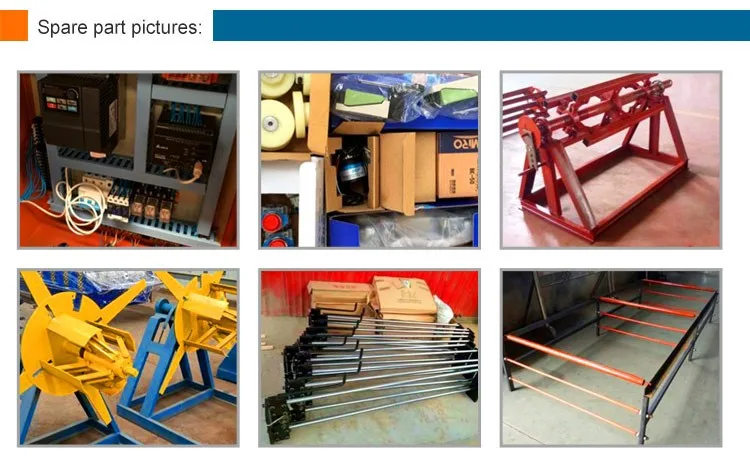

Warranty: 2 years. During the warranty period, all spare parts of the machine are covered. If any parts are damaged, replacements will be provided at no cost, although freight charges will be shared. Technical support is available for the entire life of the equipment, and overseas engineers can be dispatched as needed.

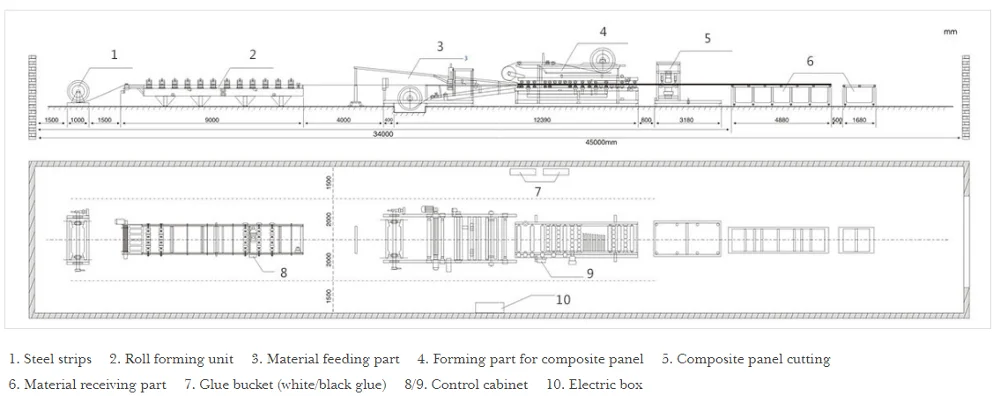

Factory Requirements: The factories using this machine should have a height greater than 5 m and an effective width of at least 45 m. A flat concrete floor is necessary, and the foundation must support a total installed power of 34 kW at 380V. Compressed air supply of 0.4-0.6 MPa and proper illumination are also required.