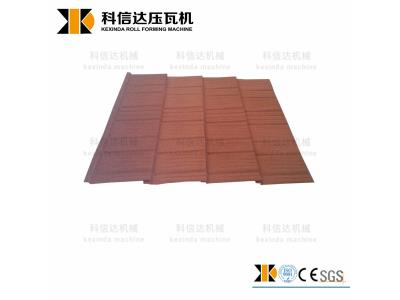

OEM ODM Panel Production Line Stone Coated Roof Tile Production Line

Product Description

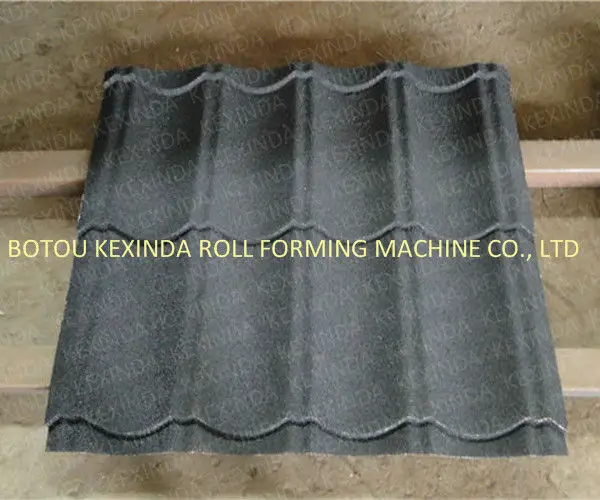

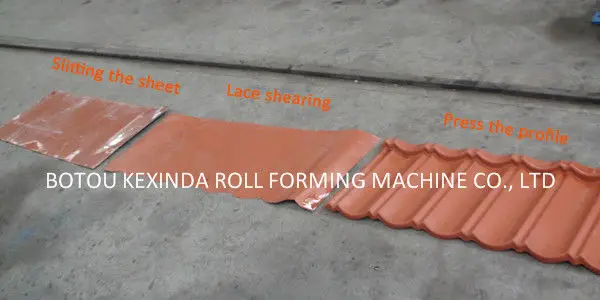

Panel Production Line for Stone Coated Roof Tiles is a revolutionary approach to roofing, utilizing a modern, environmentally friendly material based on 0.4mm Al-zinc coated steel. This production line features a unique vermiculite surface, achieved through advanced high-temperature technology, ensuring durability and aesthetic appeal. It is designed for high performance, stability, and energy efficiency, making it suitable for a wide range of roofing applications. The process is user-friendly, allowing for easy operation and maintenance.

Special offer!!! HOT!!! BEST SALES!!!

This production line is currently very popular, making it an excellent investment for those looking to enhance their roofing capabilities.

Specifications

| Feature | Details |

|---|---|

| Material | 0.4mm Al-zinc coated steel |

| Color | Vermiculite surface |

| Production Efficiency | High-performance and energy-efficient |

| Operation | Easy operation |

Detail Introduction

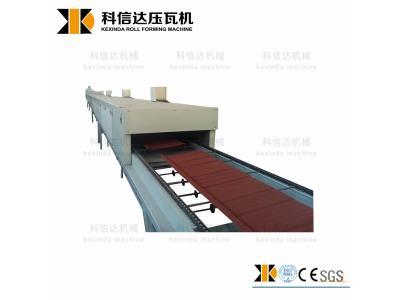

The production line consists of five main components:

- Auto bottom glue spraying section

- Auto stone coated section

- The first drying section

- Auto face glue spraying section

- The second drying section

Images