Description

The manual sheet metal curving machine is an essential piece of equipment for any tile manufacturing plant. Designed for precision and efficiency, this machine allows users to create high-quality tiles with various specifications. Its robust construction and advanced technology enable it to handle different types of steel plates, making it versatile for various applications in tile making. With adjustable parameters tailored to user requirements, this machine is perfect for businesses aiming to enhance their manufacturing capabilities.

Specifications

| Feature | Specification |

|---|---|

| Suitable Steel Plate | Color steel plate |

| Thickness | 0.3-0.8 mm |

| Feeding Width | As users needs |

| Processing Precision | Within 1.00 mm |

| Production Speed | 20-30 m/min |

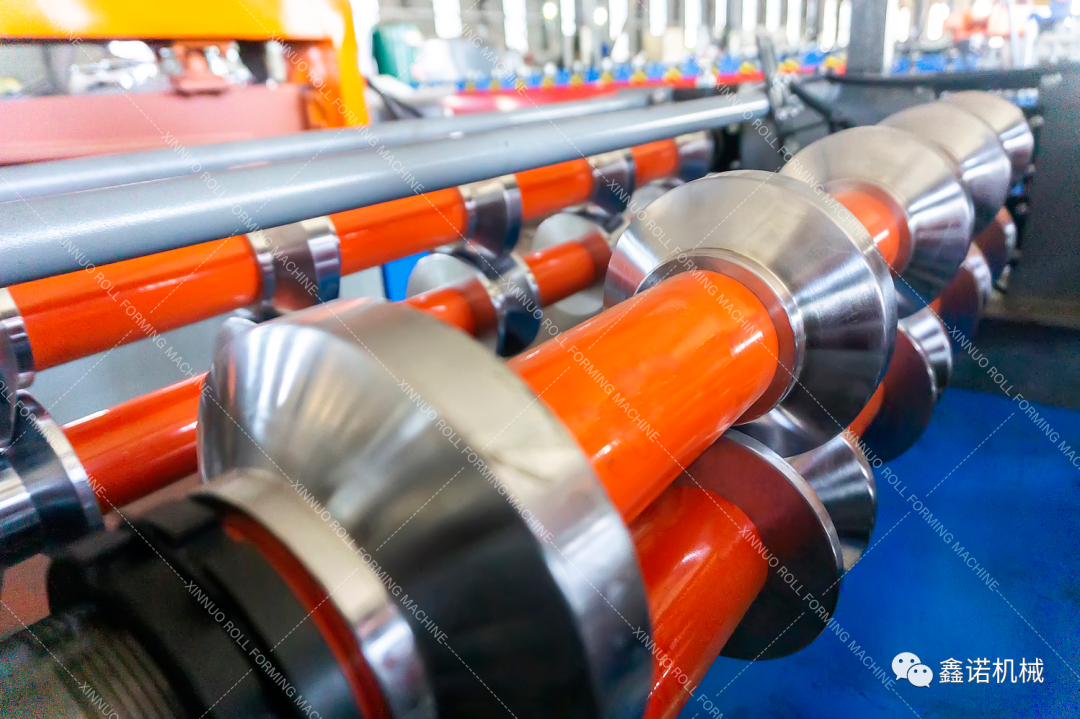

| Roller Stand | 5 rows |

| Diameter | 70 mm |

| Main Power | 3 kW |

| Pump Power | 5.5 kW |

| Side Panel Thickness | 14 mm |

| Roller Material | Carbon Steel 45# |

| Blade Material | Cr12, quenched |

| Control System | Delta PLC control |

| Voltage | 380V 50Hz 3 phases (changeable as needed) |

| Main Structure | 350 mm H-Beam |

Additional Information

Terms of Payment: 30% of the total contract value paid by T/T as down payment, the rest 70% to be paid by T/T after inspection by the buyer in the seller’s factory before delivery.

Delivery: 30 days after receipt of advance payment.

Service: A technician will be sent to your country to fix the machine. The buyer bears all costs including visa, roundtrip tickets, suitable accommodation, and a salary of $80/day for the technician.