Description

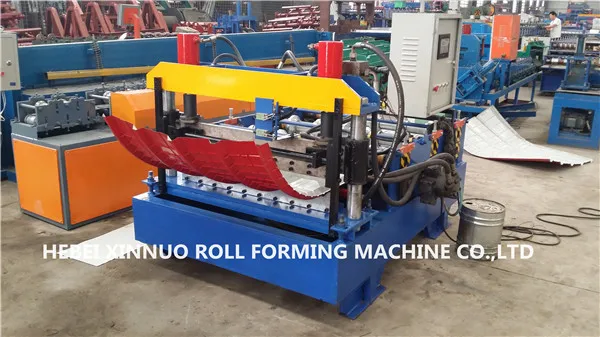

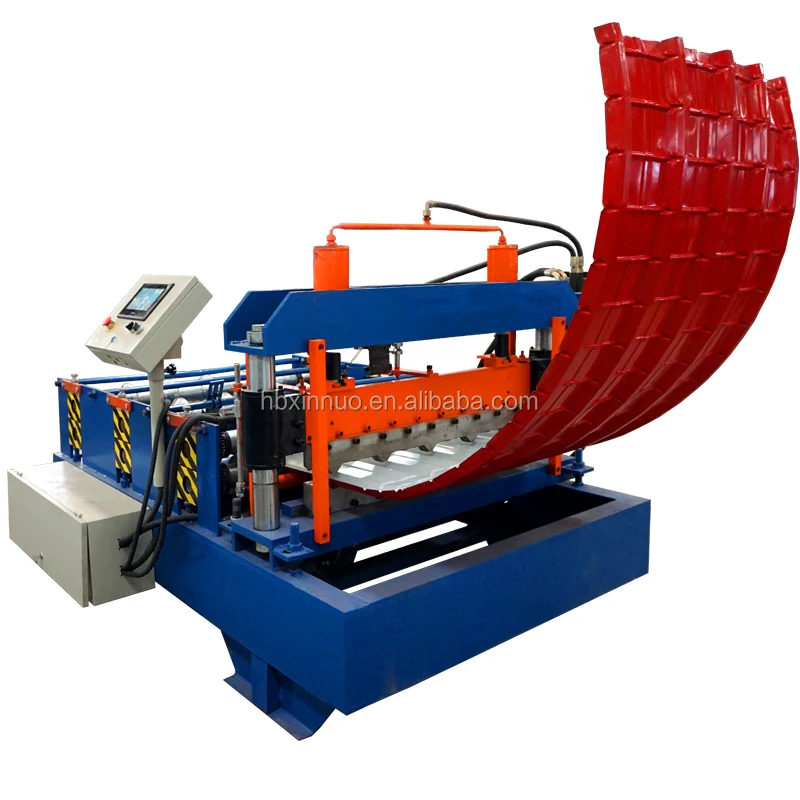

The manual sheet metal curving machine is a specialized piece of machinery designed for tile manufacturing plants. This robust and efficient machine is engineered to handle various types of steel plates, making it ideal for creating high-quality tiles. It features a user-friendly manual operation, ensuring precision in curving metal sheets for tile production.

With an emphasis on versatility, the machine accommodates different specifications based on user requirements. It is capable of processing steel plates with thicknesses ranging from 0.3 to 0.8 mm and can achieve a production speed of 20-30 meters per minute. The design includes a Delta PLC control system for enhanced operational efficiency, while its main structure is built with a 300mm H-beam, ensuring durability and stability during use.

Specifications

| Feature | Specification |

|---|---|

| Suitable Steel Plate | Color steel plate |

| Thickness | 0.3 – 0.8 mm |

| Feeding Width | As per user needs |

| Processing Precision | Within 1.00 mm |

| Production Speed | 20 – 30 m/min |

| Roller Stand | 5 rows |

| Diameter | 70 mm |

| Main Power | 3 kW |

| Pump Power | 4 kW |

| Side Panel of Machine | 14 mm |

| Roller Material | Carbon Steel 45# |

| Blade Material | Cr12, quenched |

| Control System | Delta PLC control |

| Voltage | 380V 50Hz 3 phases (changeable as needed) |

| Main Structure of the Machine | 300 mm H-Beam |

Additional Information

This machine is designed for ease of use, making it an essential tool for tile manufacturers. To ensure optimal performance, it is recommended to follow the specified power requirements and regularly maintain the machine. The company offers a service where technicians can be sent to assist with installation and maintenance, although costs for travel and accommodations will be borne by the buyer.

Product Overviews