PPR Pipe

Inquire NowDescription

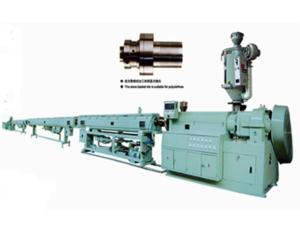

The PPR Pipe is engineered for exceptional performance in the production of polypropylene random copolymer pipes. Designed with an efficient screw specifically tailored for PP-R material, it ensures high output and stable extrusion. This advanced system is complemented by an imported automatic vacuum feeder and constant temperature dryer, facilitating seamless operation. The PCC control system from B&C, Austria, allows for fully automated production, ensuring reliable and stable performance. Additionally, the high abrasion resistance compound utilized in its durable pulling device enhances its longevity. The automatic cutting saw guarantees a flat and smooth cutting section with high precision, eliminating dust during operation. With a sieve basket die optimized for polyolefins, it achieves low melt pressure and low plasticizing temperatures, accommodating a wide processing range for specialized materials. Moreover, its long-distance communicative function enables tele-diagnosis and maintenance, making it a vital tool for efficient pipe production.

Specifications

| Feature | Details |

|---|---|

| Material | Polypropylene Random Copolymer (PP-R) |

| Control System | PCC (B&C, Austria) |

| Cutting Method | Automatic cutting saw |

| Features | High abrasion resistance, tele-diagnosis capability |

| Vacuum Feeder | Imported automatic |

| Temperature Control | Constant |

Additional Information

For optimal performance, ensure regular maintenance of the equipment and follow the manufacturer’s guidelines for setup and operation.