double layer roof panel double decker roll forming machine

Inquire NowDescription

The double layer roof panel double decker roll forming machine is designed to produce high-quality roofing panels efficiently and effectively. This advanced machine allows for the simultaneous formation of two different roofing profiles, making it ideal for construction and roofing applications. The machine is compatible with various materials, including color steel plates, galvanized sheets, and aluminum coils, ensuring versatility in production.

This model, specifically the 836+840 double layer metal roofing sheet machine, is engineered for optimal performance. It boasts a user-friendly interface and robust construction, providing reliability and durability for long-term use in industrial settings.

Specifications

| Parameter | Description |

|---|---|

| Suitable to process | Color steel plate, galvanized sheet, aluminum coils, etc. |

| Width of the feeding material | 914-1250mm |

| Roller station | 11-18 rows or custom as customer’s requirements |

| Thickness of feeding material | 0.3-0.8mm |

| Productivity | 8-12m/min |

| Rollers’ material | 45# steel |

| Diameter of shaft | 70-80mm |

| Voltage | 380V 50Hz 3phases |

| Wall thickness of main forming machine | 12-18mm steel plate |

| Main forming machine body | 300-400 mm H steel |

| Motor power | 4-7.5 kw |

| Weight | About 5-15T |

| Custom | According to customer’s requirements |

Additional Information

Guarantee: 12 Months guarantee. If any part of the machine is broken, we will supply the best part. However, if the damaged parts are due to operational errors, the buyer will pay for the shipping fee.

After-sale service: We will send a technician to your country to fix the machine. The buyer should bear all costs including visa, roundtrip ticket, suitable accommodation, and a salary of $100/day for the technician.

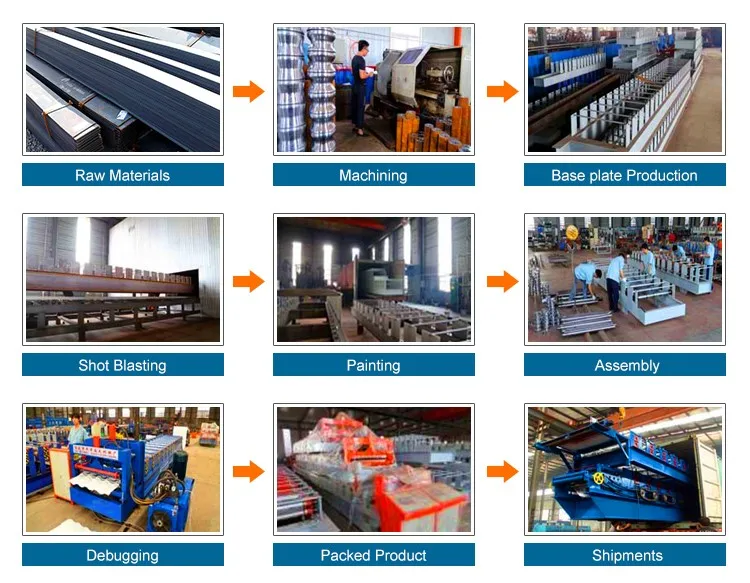

Product Images