EPS Sandwich Panel Production Line Chinese Manufacturer

Inquire NowDescription

The EPS Sandwich Panel Production Line is a state-of-the-art solution designed for the efficient manufacturing of sandwich wall panels. This advanced production line utilizes a combination of EPS, rock wool, and glass silk floss to create high-quality panels suitable for various construction applications. The Xinnuo automatic EPS sandwich roof and wall panel roll forming machine is engineered for high precision and stability, incorporating a PLC control system for ease of operation.

Key features include:

- Coil material options: EPS, rock wool, and glass silk floss.

- Plate thickness range: 0.3-0.8mm.

- Core thickness options: 20-300mm.

- Production capacity: 2-4.5m/min, adjustable based on glue type.

- Power consumption: approximately 30KW.

- Total weight: 25 tons.

- Dimensions: Length 35000mm × Width 2500mm × Height 2600mm.

Specifications

| Attribute | Details |

|---|---|

| Coil Material | EPS, Rock Wool, Glass Silk Floss |

| Plate Thickness | 0.3-0.8mm |

| Core Thickness | 20-300mm |

| Production Capacity | 2-4.5m/min |

| Total Power | About 30KW |

| Weight | 25 tons |

| Dimensions | Length 35000mm × Width 2500mm × Height 2600mm |

Additional Information

Terms of Payment: 30% of the total contract value as down payment via T/T, with the remaining 70% due after buyer inspection at the seller’s factory prior to delivery.

Delivery: 60 days after receipt of advance payment.

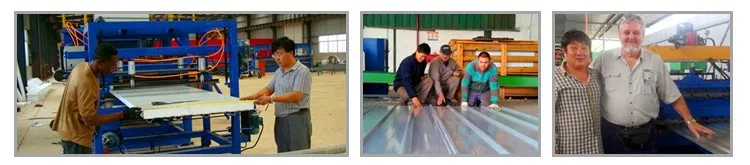

Service: Technicians will be sent to assist with machine setup. The buyer covers all related costs including visa, round-trip tickets, accommodation, and a daily salary of $60 for the technician.

Warranty: 12 months limited warranty; parts are free during warranty but shipping fees are the responsibility of the buyer.

Note: Custom designs are available based on customer specifications, and all plate types can be modified as needed.

Product Pictures