manual roof tile making machine automatic metal downpipe making machine sheet forming roll

Inquire NowDescription

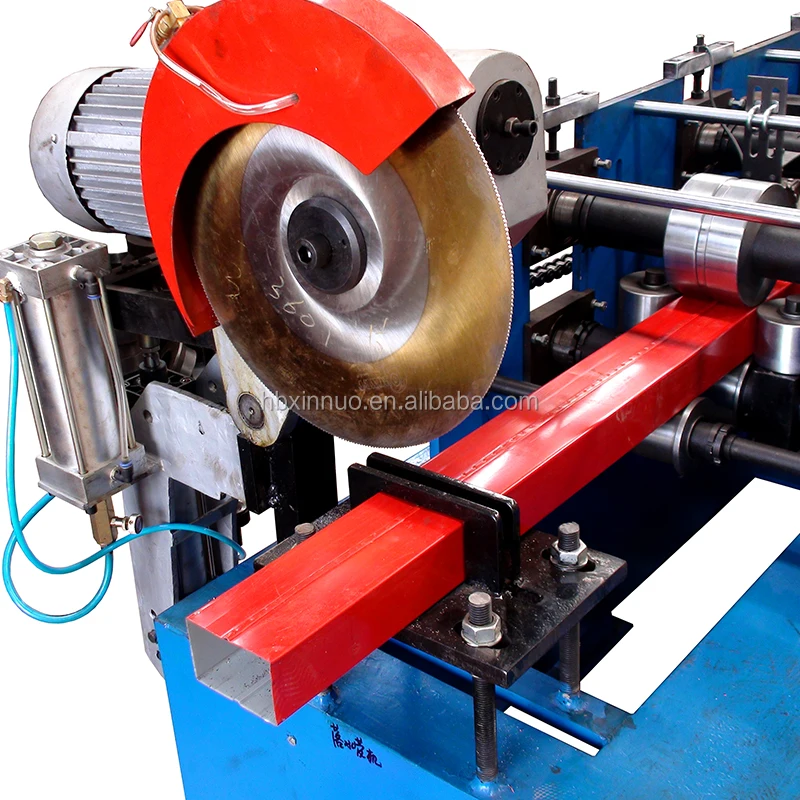

The manual roof tile making machine is a versatile and efficient solution for producing roof tiles and metal downpipes. This automatic metal downpipe making machine excels in sheet forming and roll tasks, ensuring high-quality outputs with durability and precision. Its cold roll forming technology allows for seamless bending of pipes, providing a robust connection that enhances project integrity and aesthetics. With a longer lifespan compared to traditional PVC pipes, this machine is perfect for professionals seeking reliability and efficiency in their construction projects.

Specifications

| Attribute | Details |

|---|---|

| Suitable to Process | Color Steel Plate |

| Width of the Plate | 200-600mm |

| Rollers | 14-16 rows |

| Dimensions | 8.6*0.8*1.2 m |

| Power | 4+3 kW |

| Thickness of the Plate | 0.3-0.8 mm |

| Productivity | 8-12 m/min |

| Diameter of the Roller | 52 mm |

| Weight | About 4.5 T |

| Voltage | 380V 50Hz 3 phases |

| Rolling Material | Carbon Steel 45# |

| Material of the Cutting Plate | Cr12 |

| Processing Precision | Within 1.00 mm |

| Control System | PLC Control |

| Side Panel of Machine | 14 mm |

| Main Structure of the Machine | 300 H Steel |

| Weight (Main Structure) | About 4.6 T |

Additional Information

Equipment components include a manual uncoiler, roll forming machine, computer control system, hydraulic control system, cutting, and run-out table, ensuring comprehensive functionality for efficient production.