kexinda Hose Crimping Machine Welded Pipe Mill Roll Forming Machine Factory

Inquire NowDescription

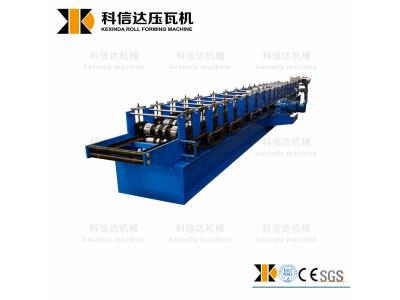

The Kexinda Hose Crimping Machine is a state-of-the-art welded pipe mill roll forming machine designed for precision and efficiency in metal processing. Controlled by a gear wheel oil pump, this machine begins its operation by driving the cutter to perform cutting tasks after hydraulic oil fills the tank. This robust system comprises a hydraulic tank, a hydraulic oil pump, two hydraulic pipes, and two sets of electromagnetic valves, ensuring smooth and reliable operation.

Engineered to handle a variety of materials, including GI and PPGI, the machine can process plates with a thickness of 0.3 to 0.8mm, achieving productivity rates of 8-15 meters per minute. With 23 rows of rollers and a roller diameter of 56mm, it promises durability and performance.

Specifications

| Feature | Details |

|---|---|

| Suitable Material to Process | GI & PPGI |

| Thickness of Plate | 0.3-0.8mm |

| Productivity | 8-15m/min |

| Rollers | 23 rows |

| Diameter of the Roller | 56mm |

| Dimensions (Major Structure) | 10m x 1.2m x 1m |

Additional Information

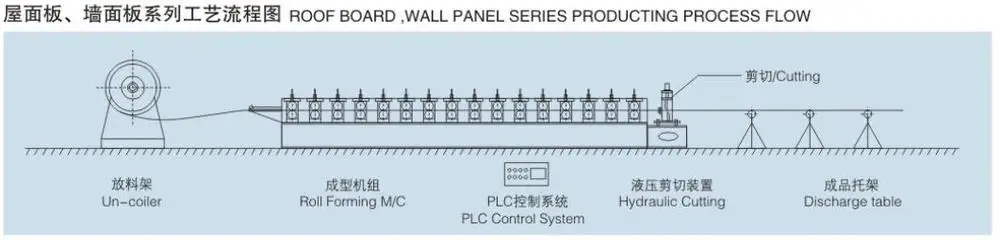

This machine includes a processing technique and deployment that covers a full line from a manual uncoiler to a roll forming machine, PLC system, hydraulic system, blade, and receiving table. The computer control cabinet utilizes Panasonic technology, allowing for adjustable lengths and two operating modes: automatic and manual. The system is designed for ease of use, enhancing productivity while maintaining precision in the manufacturing process.