Description

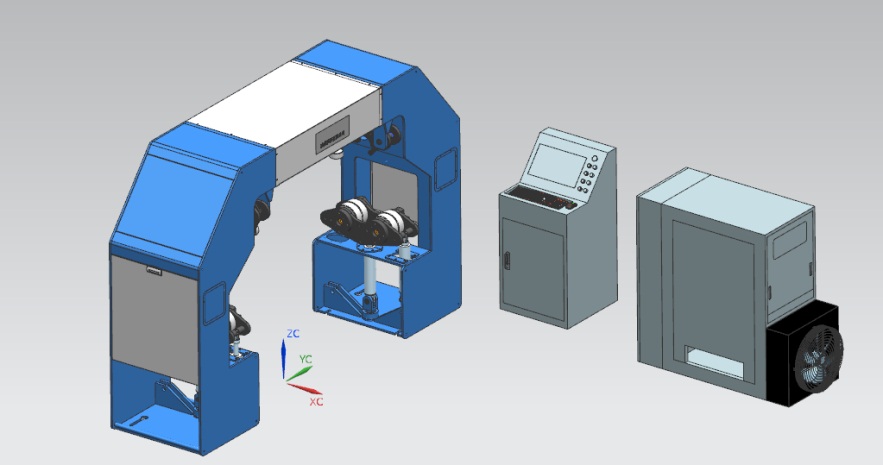

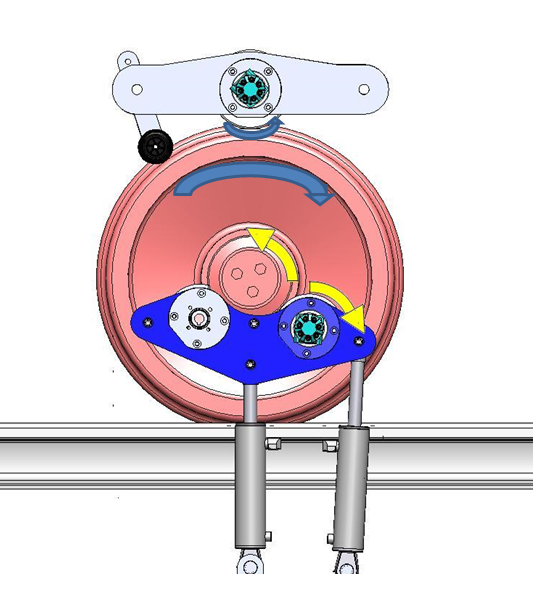

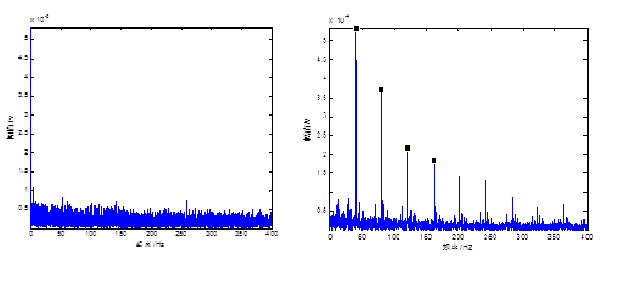

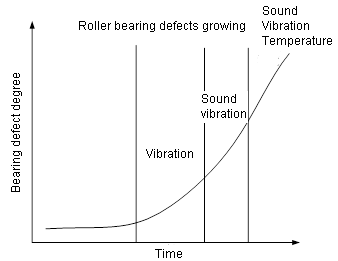

The HTK-ZJ11 Bearing Conditions Test Jig is a state-of-the-art diagnostic tool designed for depot workshops to assess the condition of bearings fixed on wheelsets. This innovative jig facilitates the rotation of the bearing cup, creating relative movement among the bearing components. As a result, vibration signals are generated and captured by an acceleration sensor, which utilizes a specialized algorithm developed by HTK to identify potential defects such as spalls and scratches on the cup, cone, and roller. The detection process for each wheelset takes approximately 3 minutes, ensuring efficient and reliable monitoring of bearing conditions.

Specifications

| Component | Description |

|---|---|

| Wheelset Jig | A platform designed for testing, equipped with mechanisms for lifting and rotating the wheelset. |

| Control Console | Allows operators to manage jig movements, input parameters, review results, and access historical data. |

| Hydraulic Unit | Provides the necessary force for lifting and rotating the wheelset, as well as applying loads on the bearings. |

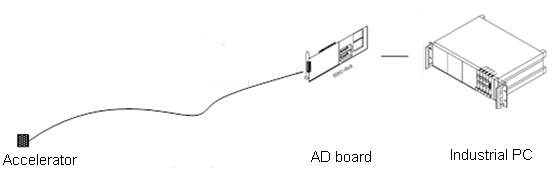

| Vibration Signal Collector | Includes an acceleration sensor, cable, AD board, and IPC for data collection. |

| Data Processing Unit | Processes collected vibration signals to identify defects and generates alarms for the operator. |

Additional Information

Over the years, three units of the HTK-ZJ11 bearing conditions test jigs have been successfully installed, starting from 2011:

| Installation | Date |

|---|---|

| Pilot installation at Harbin Depot | 2011 |

| Second installation at RHL Depot | January 2017 |

| Third installation at JMS Depot | September 2017 |

The jig has demonstrated its reliability by consistently detecting defects without missing alarms.