Description

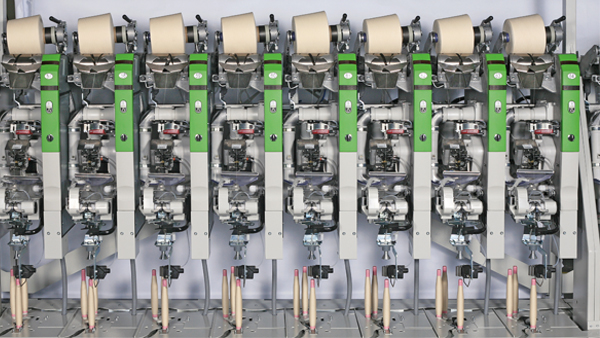

The VCRO-E Automatic Yarn Winding Machine represents the cutting edge of yarn winding technology. Developed by QDHD’s research and development team, this advanced auto-winder features 72 spindles and is designed to accommodate a wide range of yarn counts from Ne.6 to the highest levels. With its patented technology, the VCRO-E is known for its stable and reliable performance, producing perfectly wound packages while simplifying operation for users.

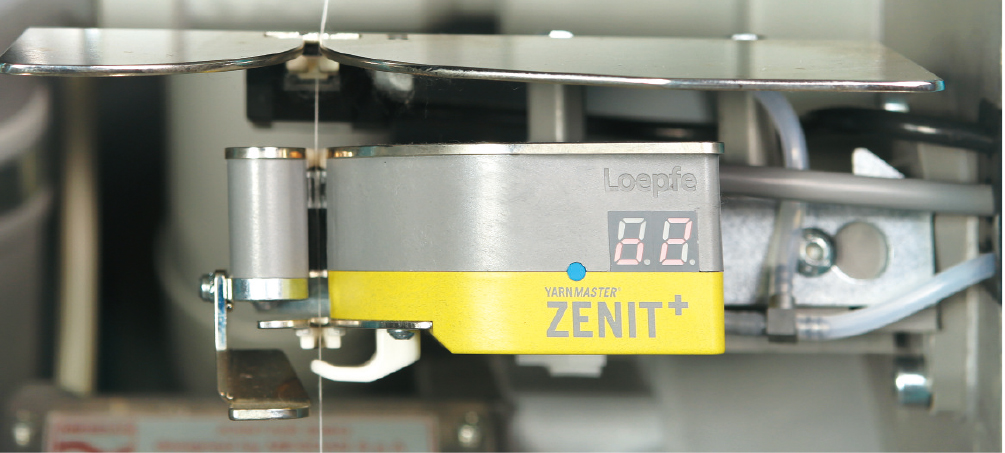

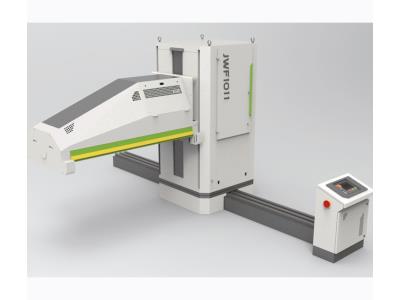

High Efficient and Intelligent Doffing Unit

- Automatic doffing with high efficiency and circle

- Traverse speed of 60m/min

- Maximum doffing package diameter of 320mm

- Smart single spindle automatic re-start feature

- Adjustable yarn fixing position for picking action

- Automatic detection of existing bobbins and packages for optimal doffing

- Flexible doffing adjustments with both manual and automatic options

- Automatic package transportation system

- Trolley traverse speed reaching 60m/min

- Efficient automatic package change with a doffing cycle of 13.5 seconds

- Pre-full wait package function enhances trolley efficiency

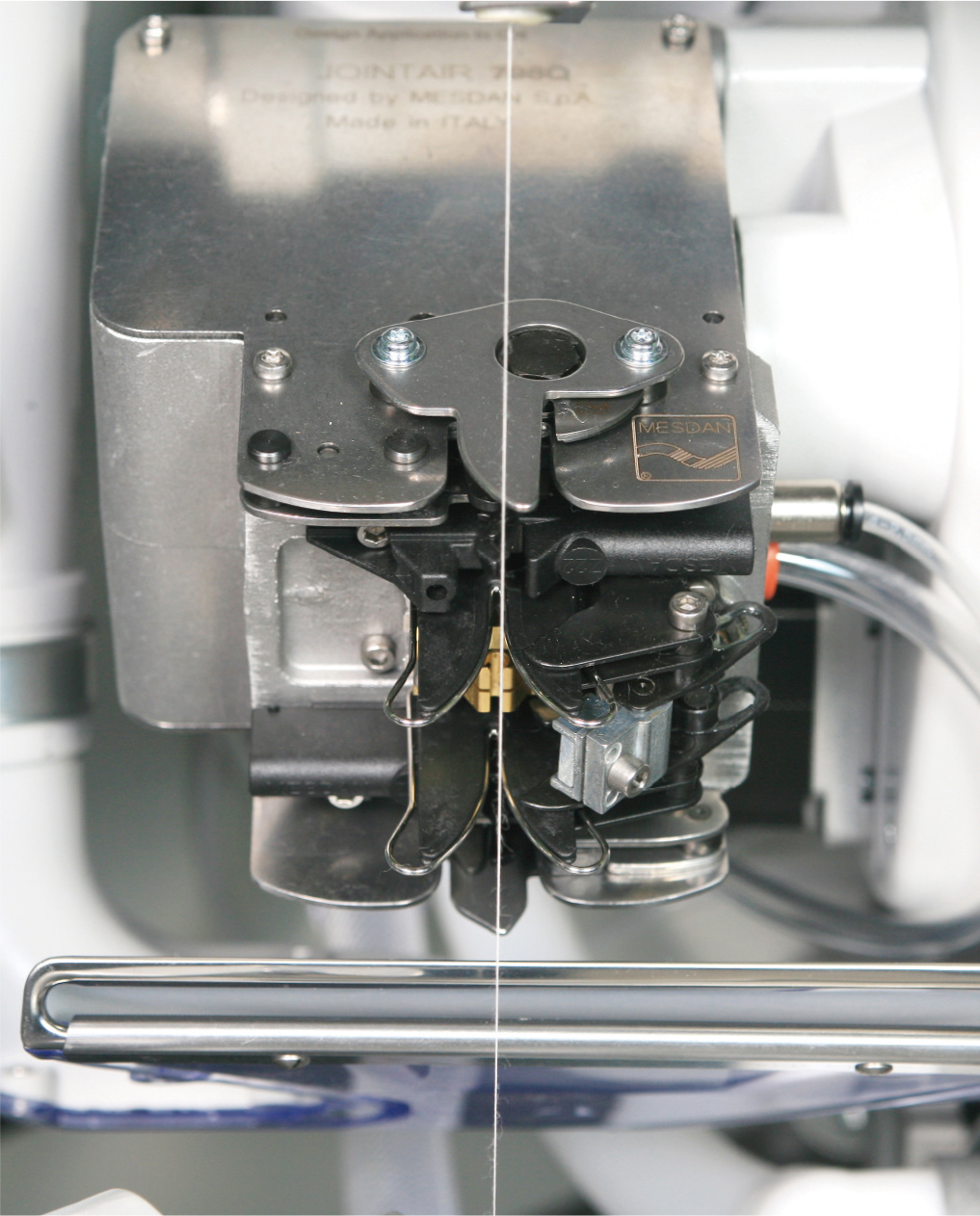

Flexible Bobbin Treatment System

- Incorporates high-grade logistics for improved efficiency

- Multi-channel logic ensures precise bobbin treatment actions

- Automatic return of empty bobbins on a conveyor loop

- Concentrated collection and identification of empty bobbins

- Compatible with various bobbin dimensions and specifications

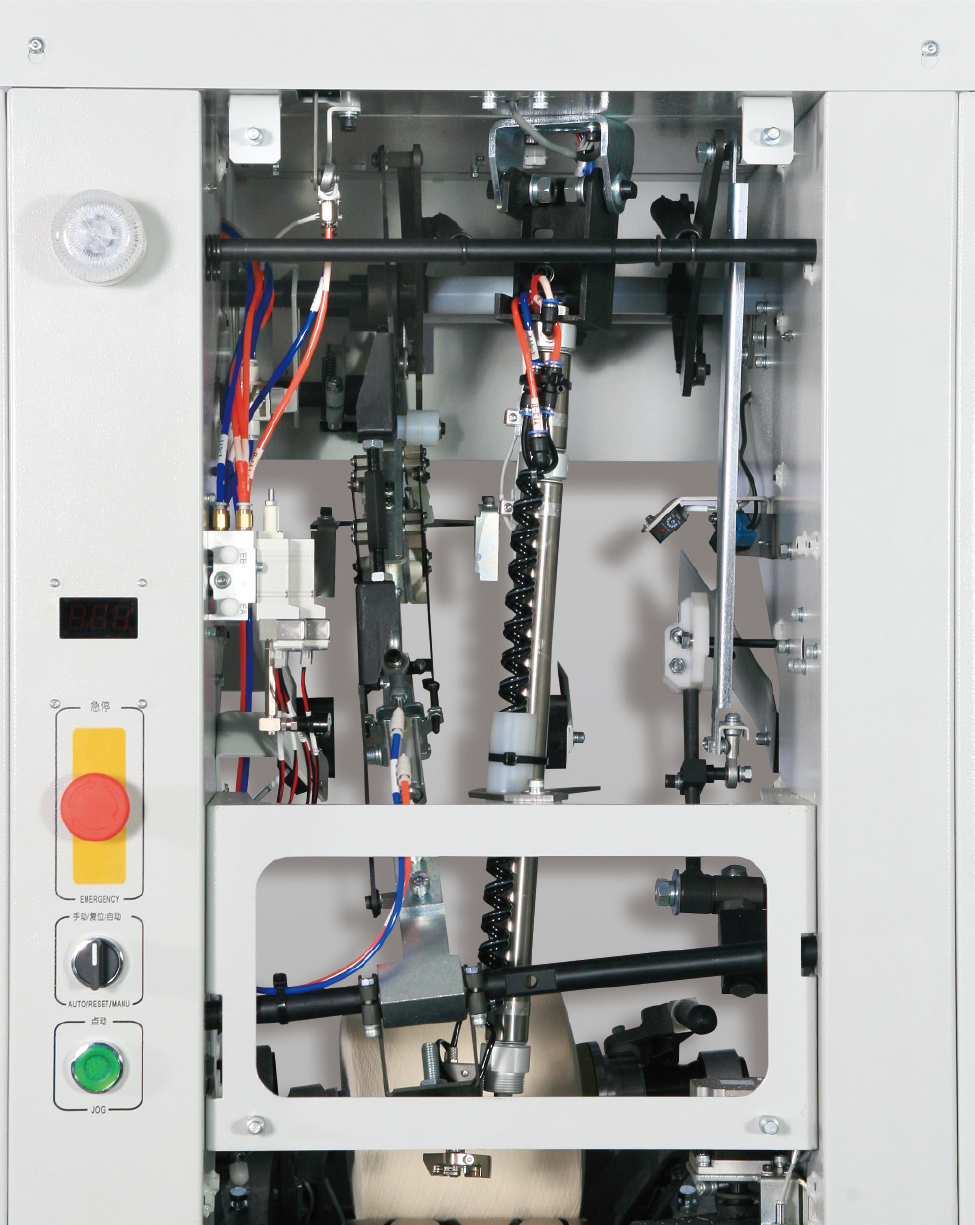

High Efficient Bobbins Delivery System

The VCRO-E utilizes a sophisticated system for transporting empty and full bobbins independently, driven by a single motor. This includes adjustments for stable and reliable belt transmission.

Specifications

| Feature | Details |

|---|---|

| Spindle Capacity | 72 Spindles |

| Yarn Count Range | From Ne.6 to highest count |

| Traverse Speed | 60 m/min |

| Max Doffing Package Diameter | 320 mm |

| Doffing Cycle Time | 13.5 seconds |

Additional Information

For optimal operation and maintenance, regular checks on the bobbin treatment system and doffing unit are recommended.