Description

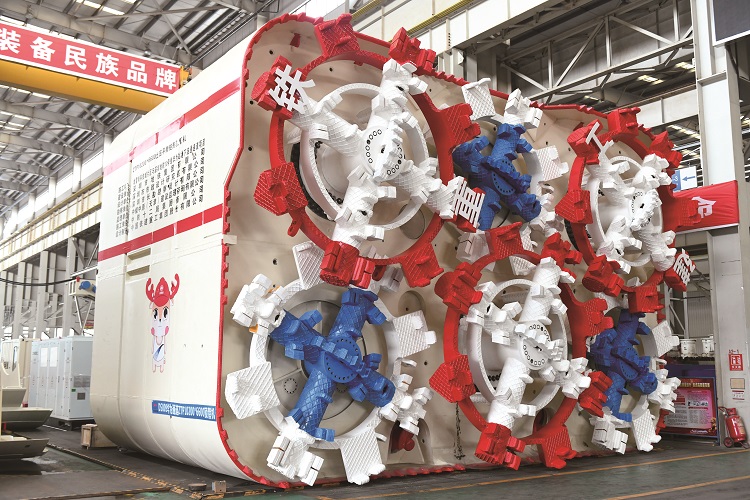

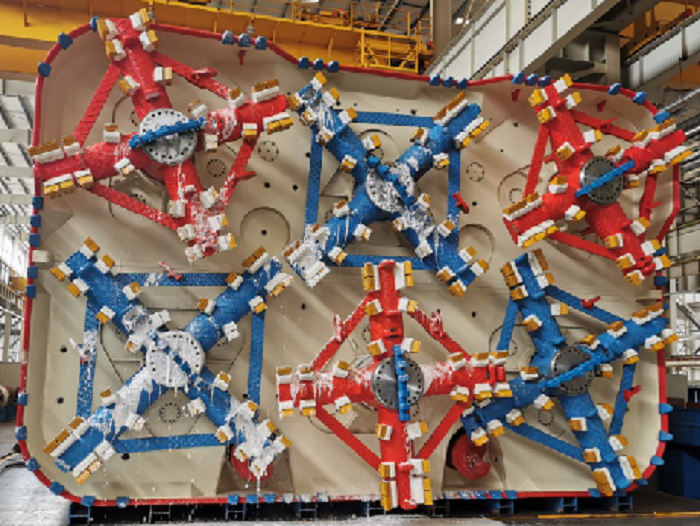

Rectangular pipe jacking machines are essential tools in modern municipal applications, renowned for their adaptability to soft soils and shallow overburdens. These machines offer superior space utilization compared to traditional circular pipe jacking machines. The machine comprises key components such as a cutterhead, shield, main drive, articulated cylinders, screw conveyors, muck car, thruster, and reaction frame. During operation, the rotating cutterhead engages with the tunnel face to excavate ground material, which is then processed in the excavation chamber. The system’s innovative design allows for efficient muck transport and the installation of specially designed box culverts through the ground, facilitating complex tunneling projects.

Working Principles: The cutterhead, equipped with cutting tools, slices through the soil, while the excavated material is mixed with additives for optimal texture. A screw conveyor moves this material to a muck car, which is lifted out via a crane. The jacking device pushes the shield and box culverts through the ground, ensuring precision and efficiency in construction.

Specifications

| No. | Project Name | Dimension (mm) | Main Geologies | Quantity |

|---|---|---|---|---|

| 1 | Huawei underground passage in Shenzhen, China | 10200*6600 | Gravel cohesive soil, completely weathered granite, intensely weathered granite | 1 |

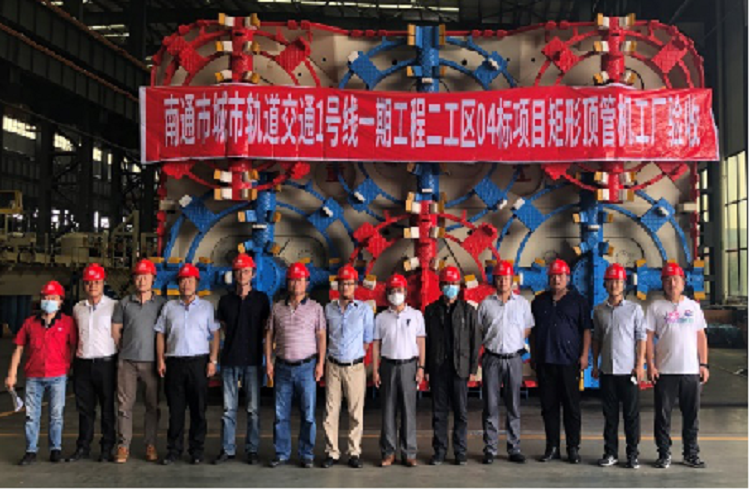

| 2 | Nantong Metro Line 1 underground passage | 7400*4900 | Artificial fill, clay, silt | 1 |

| 3 | Guangzhou Metro Line 10 underground passage | 7700*5100 | Gravel cohesive soil, completely weathered granite | 2 |

| 4 | Hangzhou Metro Line 3 underground passage | 3060 | Mucky clay, mucky silty clay | 1 |

Additional Information

Features of CRCHI’s Rectangular Pipe Jacking Machine:

- Well-arranged cutterheads with six installations for improved coverage (up to 90%).

- Hard alloy ripper bits for enhanced wear resistance and cutting capacity.

- Connectors for high-pressure water jets and quartering hammers for handling complex strata.

- Articulated cylinders for precise directional adjustments during operation.

- Block design shield for efficient handling.

- Equal thrust twin-stage cylinders that save space during launching.

- Optional bentonite friction reducing system and intermediate jacking stations for long-distance jacking.

Project Pictures