OEM ODM Shower Cooling Tunnel

Description

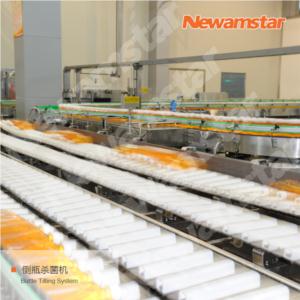

The Shower Cooling Tunnel is an innovative sterilization solution designed for optimal hygiene and efficiency. This advanced machine utilizes a five-stage treatment process, combining hot water spray sterilization with gradual cooling to ensure that all surfaces are thoroughly sanitized. Equipped with an automatic chlorine feed pump, users can easily adjust chlorine levels based on water supply, enhancing the effectiveness of the sterilization process. The system generates hot water using a steam heating device, with the ability to recycle used water through a specially designed rack sink and spray pump.

To maintain the ideal temperature, the heating device automatically warms the water if it falls below the set threshold. Conversely, if the water temperature exceeds the desired level, a circulation pump diverts the excess to an external cooling tower for efficient temperature control. The dynamic transition system at the entry and exit points minimizes stress on the inverted bottle sterilization machine, reducing the need for manual intervention.

Specifications

| Feature | Details |

|---|---|

| Treatment Stages | Five-stage hot water spray sterilization and cooling |

| Chlorine Feed | Automatic, adjustable based on water supply |

| Heating Source | Steam heating device |

| Water Recycling | Used water flows into rack sink for reuse |

| Temperature Control | Automated heating and cooling systems |

| Dynamic Transition | Minimizes bottle squeeze and manual intervention |