Description

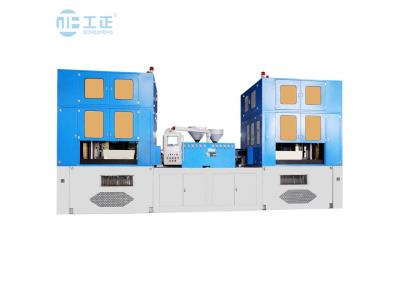

The TH series is a state-of-the-art One Step Three Stations Injection Stretch Blow Molding machine, designed for efficiency in the production of various plastic products. Its three-station setup—comprising injection, blowing, and ejection—enhances productivity while utilizing the residual temperature to directly blow the bottles, resulting in significant energy savings. This machine is particularly suited for industries such as LED lighting, pharmaceuticals, healthcare, and cosmetics, where high-temperature plastic blowing is essential.

Specifications

| Specification Item | Unit | Data |

|---|---|---|

| Screw Diameter | mm | 60 |

| Maximum Turning Radius | mm | 450 |

| Injection Capacity | g | 565 |

| Injection Clamping Force | kN | 430 |

| Blow Clamping Force | kN | 222 |

| Blow Air Injection | kgf/cm² | 35 |

| Working Pressure | kgf/cm² | 8 |

| Motor Power | kW | 45+11 |

| Heating Capacity | kW | 17.5 |

| Machine Weight | kg | 9500 |

| Dimension (L*W*H) | m | 4.6*1.8*3.3 |

Additional Information

The GZ450-THSIII model allows for various configurations, accommodating different numbers of cavities and dimensions for both the bottle neck and body, catering to a wide range of production needs. The machine is designed to maximize efficiency and minimize energy consumption, making it an ideal choice for manufacturers looking to enhance their production capabilities.