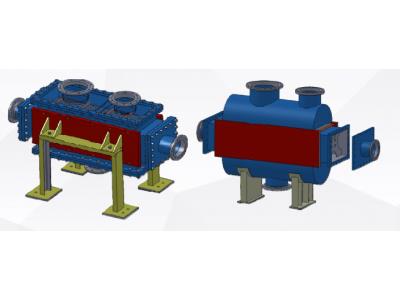

OEM ODM Welded plate & frame heat exchangers

Description

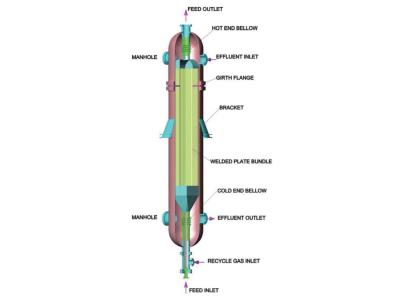

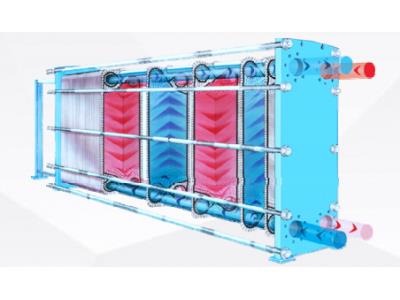

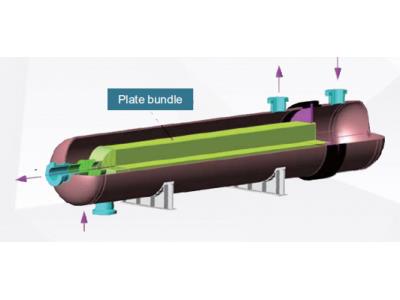

The Welded Plate & Frame Heat Exchangers are designed for a variety of cooling, heating, evaporation, and condensing applications. Featuring a unique all-welded design with corrugated plates, these heat exchangers eliminate the need for gaskets, resulting in a compact unit that delivers high efficiency through turbulent flow in a true counter-current direction. Their reduced size and material usage make them one of the most economical choices for heat transfer, perfect for industries requiring reliable thermal management.

Specifications

| Parameter | Details |

|---|---|

| Temperature | -100°C to 350°C |

| Pressure | Vacuum to 35 bar (both sides) |

| Capacities | Up to 4000 m³/h |

| Connections | 1″ to 20″ studded or flanged |

| Surface Area | 5 to 1900 m² |

| Plates Material | AISI 304, 316L, S32205, S31254, Nickel Alloy, Titanium, Ti-Pd Alloy |

| Plate Thickness | 0.6 mm to 1.0 mm |

| Frame Material | Painted carbon steel or stainless steel |

| Connections Material | Same as plates |

| Codes and Standards | ASME, PED, GOST, GB |

Additional Information

These heat exchangers are built to meet stringent industrial standards, ensuring reliability and performance in demanding environments. Their versatile design allows for efficient operation across a broad range of applications.