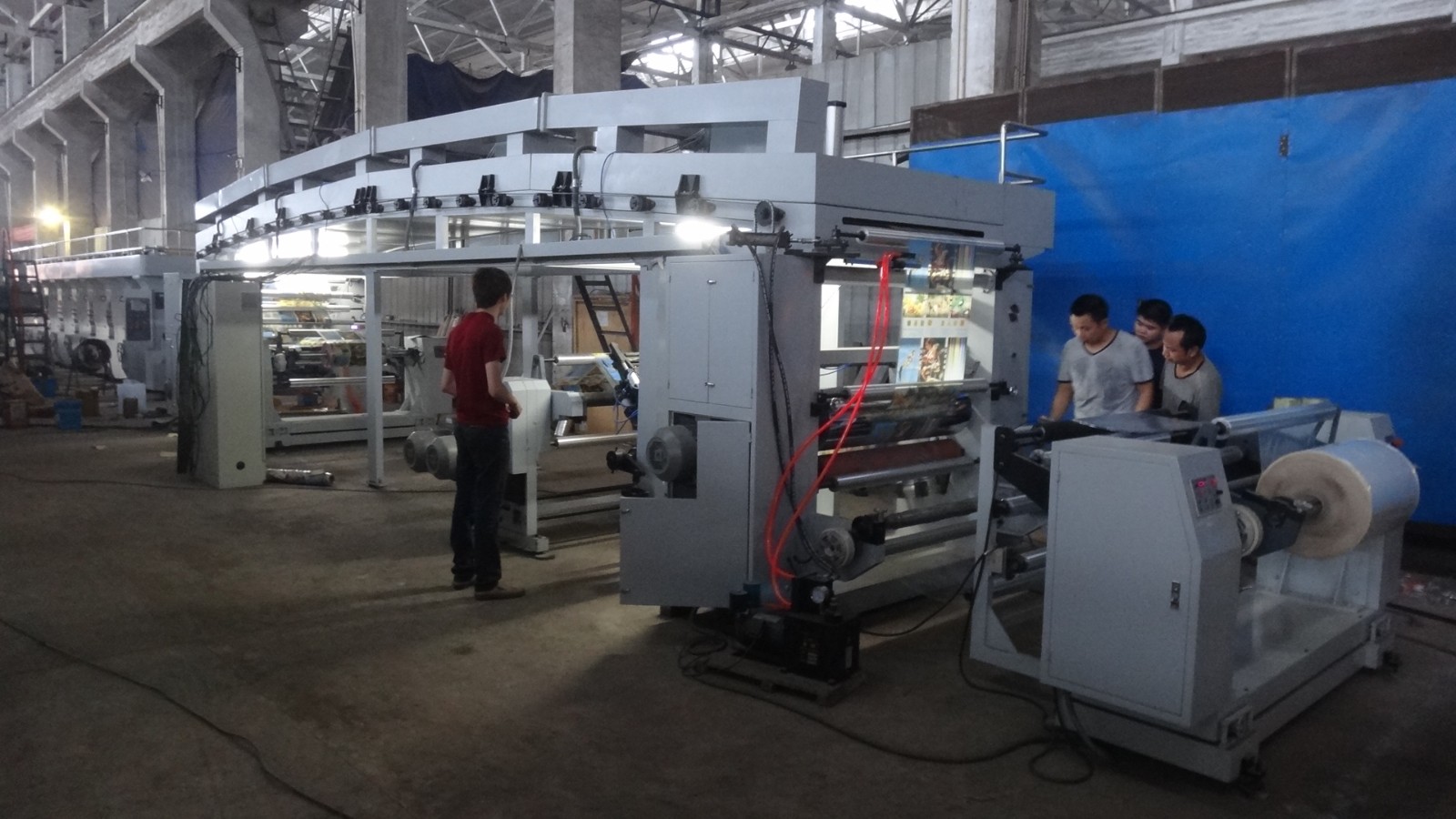

OEM ODM Dry Type Laminating Machine

Description

The Dry Type Laminating Machine is an innovative solution designed to combine light, electricity, and pneumatic functions in one compact and intelligently designed unit. This machine offers advanced features for efficient lamination processes, making it an essential addition to any production line.

Equipped with a double inverter speed adjustment, the machine ensures precise control during operation. The anilox roller delivers a consistent supply of glue, while the integrated signal work position allows seamless rewinding and unwinding. The machine’s coating glue roll features a photocell for accurate rectification, enhancing the quality of the lamination.

The heat oven is designed with a double layer pneumatic opening for optimal heat retention, providing four segments of constant temperature hot air drying. Additionally, the tension for both unwinding and rewinding is finely controlled; magnetic powder brakes regulate unwinding tension, while a moment motor controls the rewinding tension. The laminated roll utilizes heat conducting oil to maintain optimal temperatures throughout the process.

Specifications

| Feature | Description |

|---|---|

| Speed Adjustment | Double inverter adjust speed |

| Glue Supply | Anilox roller supply glue |

| Positioning | Integrated signal work position for rewinding and unwinding |

| Coating Glue Roll | Unwinding photocell rectify |

| Heat Oven | Double layer pneumatic type with four segment constant temperature drying |

| Tension Control | Unwinding tension controlled by magnetic powder brake |

| Rewinding Control | Moment motor control for rewinding tension |

| Heat Conducting | Heating drum uses heat conducting oil |

Additional Information

- Compact structure for efficient use of space.

- Equipped with a guide roll linked to the main machine for enhanced performance.