Description

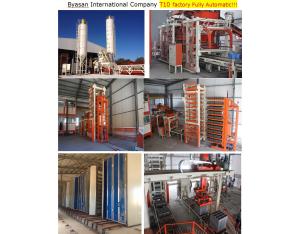

The QGM Zenith T10 Concrete Brick Making Machine is a state-of-the-art solution for producing high-quality concrete blocks and masonry products. Established in 1979, QGM has emerged as a leading block machine manufacturer with a legacy that speaks volumes about its commitment to quality and innovation. The machine integrates advanced technology, featuring a Siemens PLC touchscreen and ABB motors, ensuring efficient and reliable operation. Following the acquisition of 40 German engineers in 2012, QGM has enhanced its manufacturing capabilities, establishing a global R&D center in Emden, Germany. With the Zenith T10, you can expect optimal performance and production efficiency tailored for various applications in construction and landscaping.

Specifications

| Feature | Details |

|---|---|

| Production per mould (Hollow block: 400×200×200mm) | 10 pcs/mould |

| Production per mould (Solid block: 240×115×53mm) | 54 pcs/mould |

| Production per mould (Interlocking block: 225×112.5×60mm) | 27 pcs/mould |

| Production per mould (Holland brick: 200×100×60-80mm) | 35 pcs/mould |

| Cycle time | 15-25 seconds (Depending on product type) |

| Production per shift (8 working hours) | Hollow block: 14400-19200 pcs; Solid block: 77760-103680 pcs; Interlocking block: 31104-38880 pcs; Holland brick: 40320-50400 pcs |

| Vibration frequency | 2940 rolls/minute or 50-60 Hz |

| Vibrating force | 100 kN |

| Motor power | 48 kW |

| Gross weight | 9.0 T (without face mix device); 12 T (with face mix device) |

| Total power | 39.85 kW |

| Raw materials | Crushed stone, sand, cement, dust, coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial waste |

| Applicable products | Concrete blocks, solid/hollow/cellular masonry products, paving stones, garden and landscaping products |

| Applied fields | Buildings, road paving, squares, gardens, landscaping, city constructions |

Additional Information

Big Five Advantages of QGM Automatic Block Making Machines:

- Utilizes Germany Siemens PLC control system for stability and reliability.

- Features Frequency Conversional Control Technology, enhancing production efficiency by 30%.

- Employs Double high-dynamic Proportional/Directional Valves for smooth operation and stability.

- Incorporates 360° Multi-Shaft Rotating and Compulsory Feeding for uniform mixing and density.

- Subjected to heat treatment for enhanced durability and extended machine lifetime.