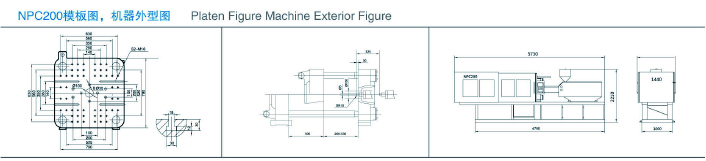

OEM ODM PLASTIC INJECTION MOLDING MACHINE NPC 200

Description

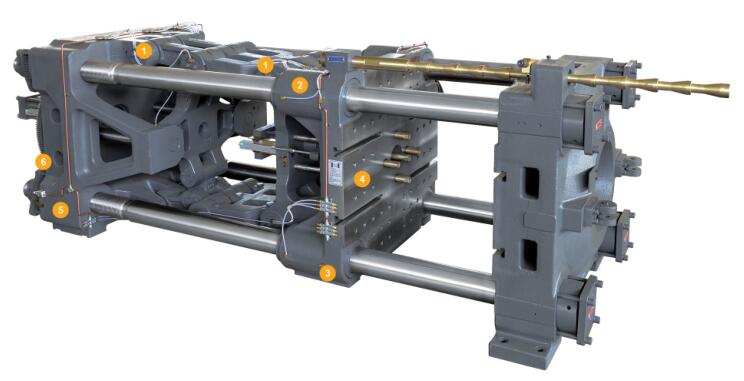

The Plastic Injection Molding Machine NPC 200 is designed for precision and reliability in the production of plastic components. This advanced machine features a robust clamping unit that ensures strong rigidity and stable operation, utilizing a diagonal type dual toggle mechanic for effective mold clamping. With an automatic centralized lubrication system and a standard interface for neutron devices, the NPC 200 is engineered for efficiency and ease of maintenance.

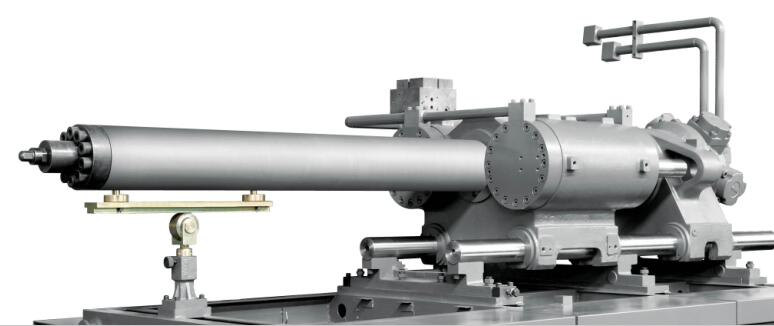

Its injection unit boasts a dual-cylinder balanced injection system for accurate injection and stable operation. The machine supports multi-stage injection pressure, speed, and position control, ensuring high-quality production. The hydraulic unit incorporates imported components, enhancing the system’s response speed and reliability.

Equipped with a high-end controller, the NPC 200 enables complete production network management, allowing for data cloud connectivity and real-time monitoring of production states. With features designed for user-friendliness, such as a one-key mold opening and closing function, this machine minimizes wear and maximizes efficiency.

Specifications

| Feature | Details |

|---|---|

| Clamping Mechanism | Diagonal type dual toggle, one-piece casting connecting rod |

| Lubrication | Automatic centralized lubrication system |

| Injection System | Dual-cylinder balanced injection with multi-stage control |

| Hydraulic Components | Imported components for improved response speed |

| Controller | High-end controller with production network management |

Additional Information

This machine is designed to reduce vibration during operation, enhancing machine life and yield. Users can benefit from fast and smooth mold operation, high-pressure clamping without impact, and easy maintenance through a centralized manual lubricating device.