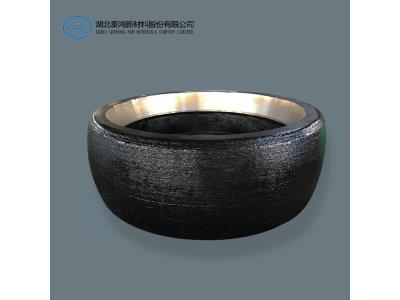

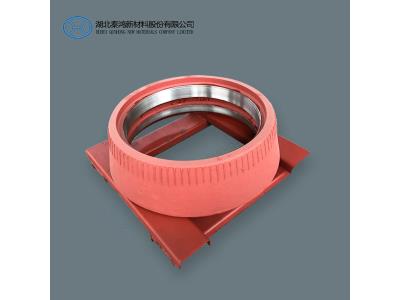

OEM ODM Cement plant raw mill,cement mill High chrome Vertical roller mill roller tyre

Description

The High Chrome Vertical Roller Mill Roller Tyre is engineered for optimal performance in cement plants. Manufactured using high-quality materials such as ASTM A532 and EN 12513 standards, this component boasts exceptional durability and wear resistance. With over 25 years of experience, the product is crafted from a metal matrix ceramic composite material, ensuring a longer lifespan—approximately 10% longer than similar domestic alternatives. This cost-effective solution not only outperforms imported products but also serves as a reliable replacement for various wear parts, including roller segments and liners. Our products have successfully been utilized in countries like Russia, Germany, Pakistan, and Argentina, demonstrating their global acceptance and reliability.

Advantages: The wear-resistant parts produced by our company provide superior price performance, significantly improving operational efficiency and reducing maintenance costs for users in the cement and electric power industries.

Corporate Strength: Established in 1993, our company has a rich history of producing wear-resistant materials and has built a robust network of over 400 long-term cooperative users. Our partnerships with renowned mill manufacturers such as Citic Heavy Industries and Germany’s FL Smidth enhance our credibility in the global market.

Main Products: We offer a wide range of roller segments and table segments for vertical mills, compatible with brands like FL Smidth ATOX, Loesche LM, and GEBR. PFEIFFER, among others. Customization options are available to meet specific client requirements.

Specifications

| Attribute | Details |

|---|---|

| Material | High Chrome Metal Matrix Ceramic Composite |

| Standards | ASTM A532, EN 12513, GB/T8263 |

| Experience | 25 years in production |

| Exported Countries | Russia, Germany, Pakistan, Costa Rica, Argentina, Greece |

Additional Information

Customization of products is available based on specific needs and requirements, ensuring that clients receive tailored solutions for their vertical mill applications.