OEM ODM brake disc vertical grinder

Description

The CMFK-L450 brake disc grinder is a high-precision, high-load vertical CNC lathe designed for robust performance in various industries, including machinery manufacturing and automotive. Featuring a cutting-edge X-axis positioning moving column structure, this grinder minimizes thermal deformation while optimizing shock absorption, ensuring precise machining of complex workpieces. Built from high-grade cast iron, the grinder boasts exceptional seismic and tensile strength.

Equipped with a high-speed, high-precision spindle head that utilizes NSK bearings, the CMFK-L450 guarantees reliable performance during extensive cutting operations, enhancing the spindle’s longevity. Its heat-treated and precision-ground ball screws further contribute to the grinder’s accuracy and durability.

To ensure seamless operation, the brake disc grinder includes an automatic lubrication system, facilitating timely maintenance. An imported eight-station electric turret tool rest allows for rapid tool changes, significantly boosting work efficiency. Additionally, the numerical control system can be customized with either an absolute position encoder system or a servo numerical control system based on user requirements.

The protective folding cover is designed with a back-shaped structure to prevent chips and liquids from compromising internal components, thus extending their service life. With a balanced operation and double protection for the bearing seat, the CMFK-L450 brake disc grinder exemplifies reliability and innovation in CNC machining.

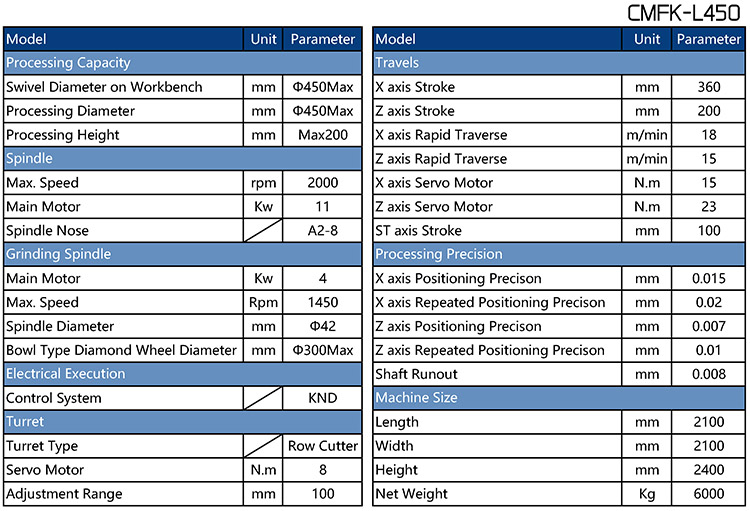

Specifications

| Attribute | Details |

|---|---|

| Type | Vertical CNC Lathe |

| Material | High-grade Cast Iron |

| Spindle Bearings | NSK Bearings |

| Tool Rest | Eight-station Electric Turret |

| Lubrication | Automatic Lubrication Device |

| Control System | Absolute Position Encoder or Servo Numerical Control |

Additional Information

The inner protective cover’s innovative design prevents the ingress of chips and liquids, ensuring the longevity of functional components. The absence of false rails contributes to a balanced operation, while the double protection for the bearing seat enhances durability.