Description

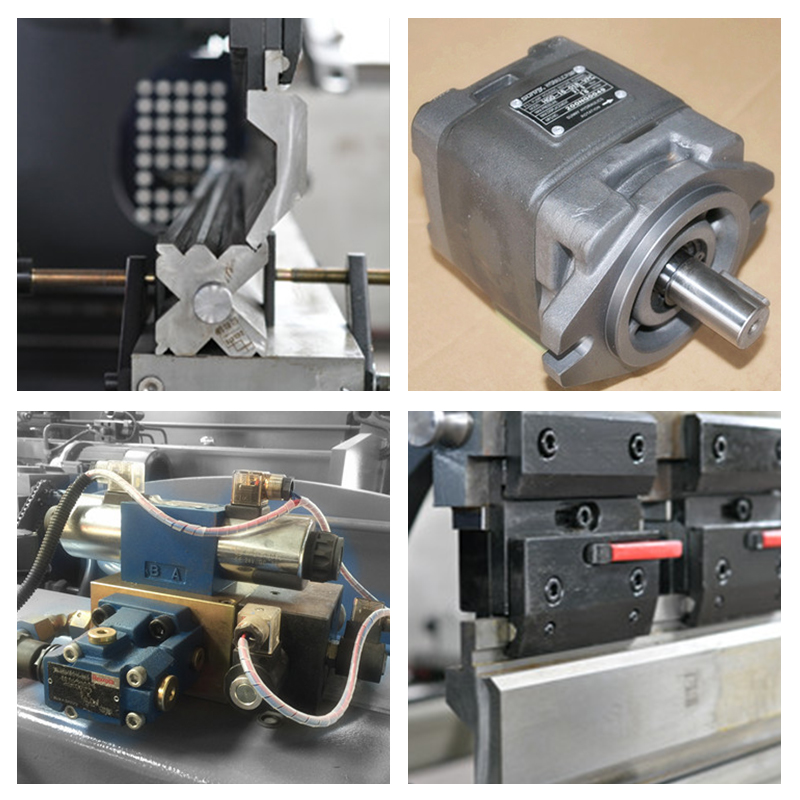

The hydraulic press brake machine is a state-of-the-art solution designed for precision bending and shaping of metal sheets. Utilizing the advanced WC67Y series press brakes, this machine features a special numerical control (NC) system from DELEM Company, ensuring exceptional accuracy and efficiency. The automated controls for the rear block stop (X) and slide block (Y) enhance operational ease, allowing for seamless adjustments during production. Additionally, the rear block stop is equipped with both ordinary and precision screw mandrels, effectively minimizing transmission clearance and maximizing performance.

Specifications

| Specification | Nominal Pressure (KN) | Length of Working Table (mm) | Throat Depths (mm) | Ram Stock (mm) | Number of Strokes (m/min-1) | Motor Power (KW) |

|---|---|---|---|---|---|---|

| WC67Y/K-40/2200 | 400 | 2200 | 200 | 100 | 11 | 4 |

| WC67Y/K-40/2500 | 400 | 2500 | 200 | 100 | 11 | 4 |

| WC67Y/K-50/2500 | 500 | 2500 | 200 | 100 | 11 | 5.5 |

| WC67Y/K-63/2500 | 630 | 2500 | 250 | 100 | 10 | 5.5 |

| WC67Y/K-63/3200 | 630 | 3200 | 250 | 100 | 10 | 7.5 |

| WC67Y/K-80/2500 | 800 | 2500 | 320 | 150 | 8 | 7.5 |

| WC67Y/K-80/3200 | 800 | 3200 | 320 | 150 | 8 | 7.5 |

| WC67Y/K-100/2500 | 1000 | 2500 | 320 | 150 | 8 | 7.5 |

| WC67Y/K-100/3200 | 1000 | 3200 | 320 | 150 | 8 | 7.5 |

| WC67Y/K-100/4000 | 1000 | 4000 | 400 | 150 | 8 | 7.5 |

| WC67Y/K-125/2500 | 1250 | 2500 | 320 | 150 | 8 | 7.5 |

| WC67Y/K-125/3200 | 1250 | 3200 | 320 | 150 | 8 | 7.5 |

| WC67Y/K-125/4000 | 1250 | 4000 | 400 | 150 | 8 | 7.5 |

| WC67Y/K-160/3200 | 1600 | 3200 | 400 | 180 | 8 | 11 |

| WC67Y/K-160/4000 | 1600 | 4000 | 400 | 180 | 8 | 11 |

| WC67Y/K-160/5000 | 1600 | 5000 | 400 | 180 | 7 | 11 |

| WC67Y/K-160/6000 | 1600 | 6000 | 400 | 200 | 7 | 15 |

| WC67Y/K-200/3200 | 2000 | 3200 | 400 | 200 | 7 | 15 |

| WC67Y/K-200/4000 | 2000 | 4000 | 400 | 200 | 7 | 15 |

| WC67Y/K-200/6000 | 2000 | 6000 | 400 | 200 | 7 | 15 |

| WC67Y/K-250/3200 | 2500 | 3200 | 400 | 200 | 7 | 18.5 |

| WC67Y/K-250/4000 | 2500 | 4000 | 400 | 200 | 7 | 18.5 |

| WC67Y/K-250/6000 | 2500 | 6000 | 400 | 250 | 7 | 18.5 |

| WC67Y/K-300/3200 | 3000 | 3200 | 400 | 250 | 7 | 22 |

| WC67Y/K-300/4000 | 3000 | 4000 | 400 | 250 | 7 | 22 |

| WC67Y/K-300/6000 | 3000 | 6000 | 400 | 250 | 7 | 30 |

| WC67Y/K-300/7000 | 3000 | 7000 | 400 | 250 | 7 | 30 |

| WC67Y/K-400/6000 | 4000 | 6000 | 400 | 250 | 7 | 30 |

| WC67Y/K-500/6000 | 5000 | 6000 | 400 | 300 | 7 | 37 |

| WC67Y/K-600/6000 | 6000 | 6000 | 420 | 300 | 7 | 37 |

Additional Information

For optimal performance, ensure regular maintenance and calibration of the machine. This will prolong its lifespan and maintain the accuracy of your bending operations.