#### **Description**

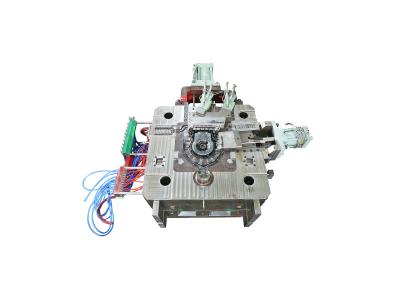

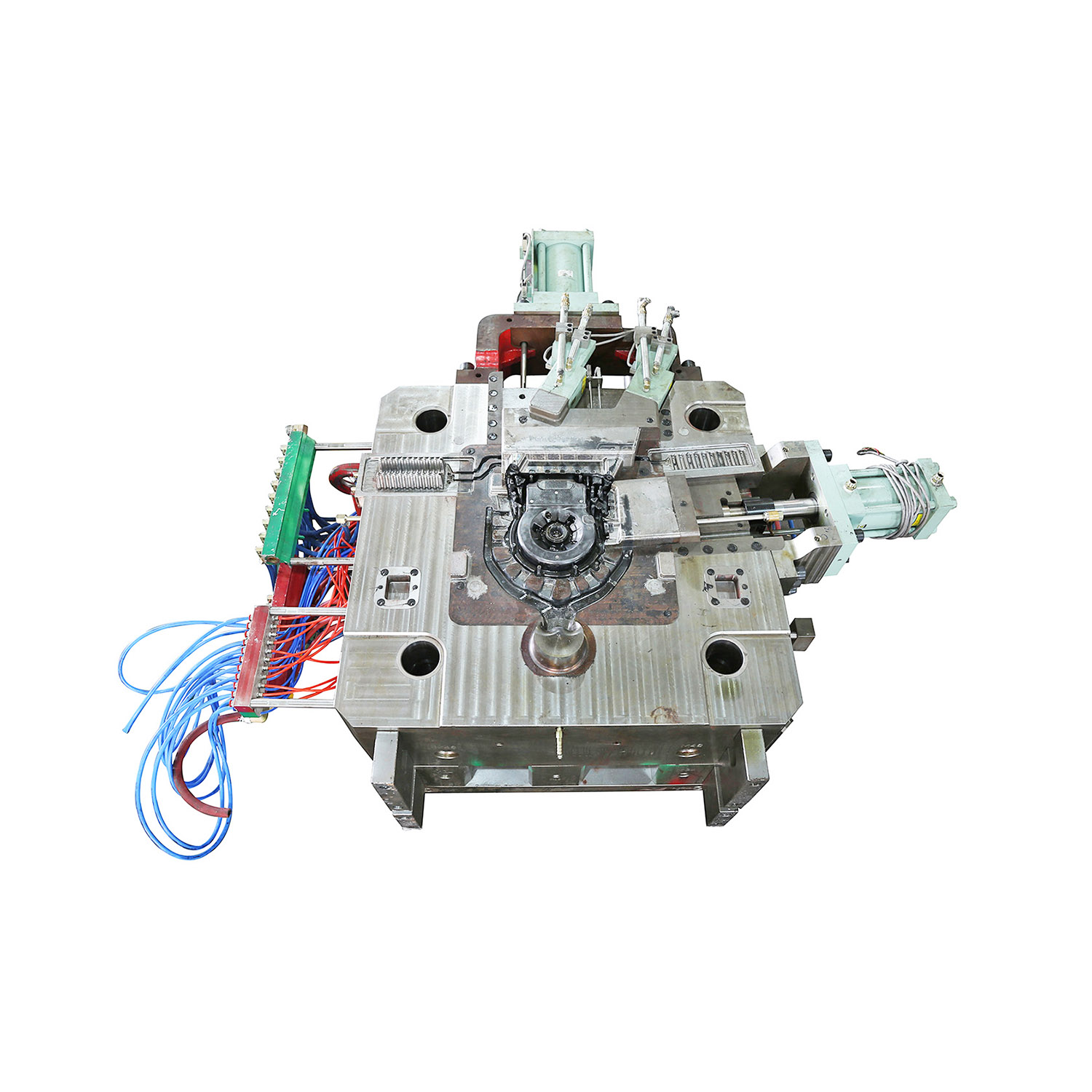

The **High Pressure Die Casting Mold** is engineered for precision and durability, designed to meet the rigorous demands of various industries. Crafted from high-quality materials such as H13, DIEVAR, and SKD61, this die casting die is ideal for producing components with complex shapes and high precision. The mold supports a wide range of casting alloys, including Aluminum and Magnesium, making it versatile for multiple applications. With options for single, multiple, or unit cavities and a tonnage capacity ranging from 200T to 4400T, this mold is perfect for both small and large-scale production. The mold life spans between 50,000 to 300,000 cycles, depending on the products, ensuring long-term use and reliability.

#### **Specifications**

| Attribute | Details |

|---|---|

| Mould Material | H13, DIEVAR, SKD61, 8407, 8418, 1.2343, 1.2344, 1.2367, 3Cr2W8V, 4Cr5MoSiV, W400, DAC55, DH-31, etc. |

| Cavity Qty | Single Cavity, Multiple Cavity, or Unit Cavity |

| Tonnage | 200T-4400T |

| Treatment | Heat Treatment, Nitriding, Polishing, etc. |

| Mold Life | 50,000 to 300,000 cycles (depending on products) |

| Lead Time | 35-60 days |

| Special Request | According to customer’s request |

| Applications |

|

#### **Additional Information**

**Our Advantages:**

1. Over 20 years of mold-making experience, certified with ISO9001 & IATF 16949, with skilled workers.

2. Extensive export experience to over 30 countries, providing tailored services to meet international standards.

3. Investment in advanced hardware and software facilities, ensuring high precision and efficiency.

4. Collaboration with world-class brands, adhering to rigorous quality control systems.

5. Direct export for cost-effectiveness, often 20-30% cheaper for mature molds.

6. Three factories ensure ample production capacity with quick response times.

7. Use of high-quality materials to guarantee long life and efficiency.