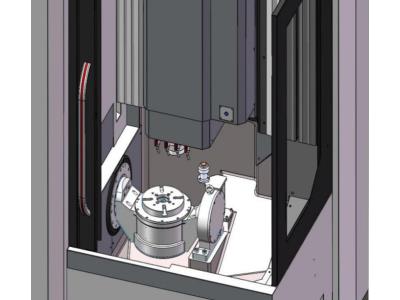

OEM ODM Vertical machining center FV1060/FV1200

Description

The Vertical Machining Center FV1060/FV1200 is engineered for precision and efficiency in machining operations. It boasts a standard configuration that includes advanced features such as a full-face shield, automatic lubrication system, and a robust tool changing system. This machine is designed to handle complex tasks with ease, providing reliability and accuracy for various machining applications. Optional configurations enhance its capabilities, offering features like a 24 knife arm type tool changing system, NC rotary table, and automatic tool length measurement, making it a versatile addition to any workshop.

Specifications

| Attribute | Unit | FV-1060 | FV-1200 |

|---|---|---|---|

| X-axis travel | mm | 1020 | 1200 |

| Y-axis travel | mm | 610 | 610 |

| Z-axis travel | mm | 610 | 610 |

| Worktable area | mm | 1200*600 | 1300*600 |

| Worktable max. load | kg | 900 | 900 |

| T-slot (number*width*distance) | T-slot number | 5*18*80 | 5*18*100 |

| X/Y/Z-axis rapid feed | m/min | 36/36/36 | 36/36/36 |

| Cutting feed speed | m/min | 10000 | 10000 |

| Spindle speed | r.p.m | 8000 | 8000 |

| Spindle motor | kw | 7.5/11 | 7.5/11 |

| Machine weight | T | 6.8 | 7.1 |

Additional Information

The FV1060/FV1200 is equipped with a robust automatic lubrication system, ensuring longevity and performance. Users can opt for the advanced tool detection system and spindle oil cooler for enhanced operational efficiency. The machine also includes a FANUC 0I-MF controller, which offers intuitive operation and precise control over machining processes. This product is ideal for industrial applications requiring high precision and operational flexibility.